Thermal Specificities:

Quiri, as a specialist of heat exchangers, can provide you a process fluids reheater.

Equipment delivered in France in 2015 on behalf of a company specialised in the lube oil additives.

This heat exchanger is part of a set of 2 exchangers installed in order to heat a polymer in a full tank of 2400 m3 from 80 to 100°C in 30 hours.

In order to design this exchanger as best as possible, a thermal study has been performed taking into account the heat losses of the tank, those of the process fluid as well as those of the line of production

The thermal design was carried out in order to heat the whole quantity of polymer of the tank in a maximum time of 30 hours.

To do so, we have designed a shell & tube heat exchanger which heats the polymer in one pass in the sequence from 80 to 140 ° C at the start of the sequence and from 100 to 146 ° C at the end of the sequence.

The function of this shell & Tube exchanger is to heat a process fluid from steam coming from the line within the plant.

The heat exchanger, of Quiri thermal design, condenses the steam on the tube side and supplies and heats the polymer on the shell side, which is reinjected into the tank after being reheated in the exchanger.

Technical Data of the reheater:

| Shell Side | Tube Side | ||||

| Nature of the fluids | Polymer / Liquid 2 | Steam / Gas 2 | |||

| Number of passes | 2 | 2 | |||

| Service Temperature (inlet / outlet) | °C | 80 | 140 | 159.01 (saturation) | 159.01 |

| Service Pressure | Bar (a) | 14 | 6 | ||

| Main Dimensions | |||||

| Power | kW | 1192 | |||

| Exchanged Area Installed | m² | 44.1 | |||

| Bundle tubes Type | Bended U-tubes | ||||

| Shell Diameter | mm | 350 | |||

Geometric Specificities :

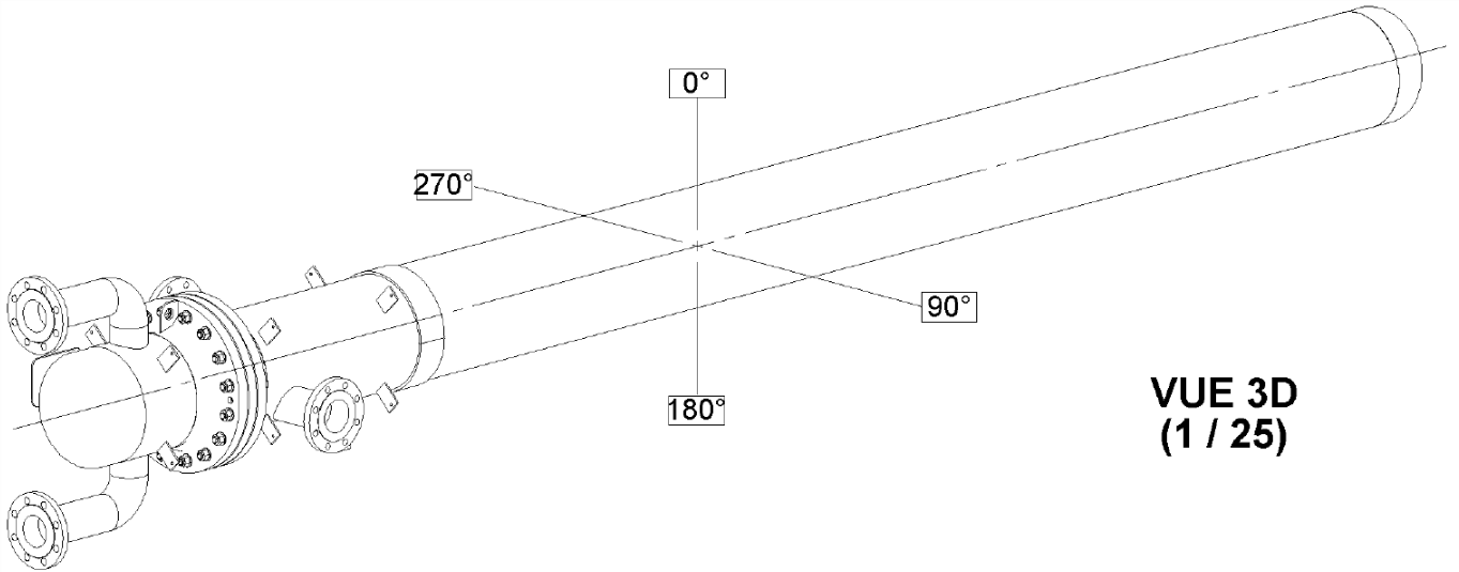

Horizontal tubular heat exchanger, overall length 5800 mm, empty weight 1500 Kg.

Shell & Tube Exchanger , type BFU – with removable head and bundle

Construction Specificities:

Code: CODAP

Regulation: DESP 97/23 / CE

Calculation temperature: -20 ° C / 195 ° C tube side and shell side

Design pressures: -1 / +13 bar (g) on the tubeside and -1 / +16 bar (g) on the shell side

Test pressures: 25 bar (g) on the tubeside and 28 bar (g) on the shell side

Risk category IV, reception modula G

Welding coefficient 0.85

Metallurgy :

| Material | Norm | |

| Shell | Gr6 | SA333 |

| Tubesheets | Gr316L | SA240 |

| Flanges | LF2 | SA350 |

| Head | WPL6 | SA240 |

| Bundle tubes | TP316L | SA213 |

| Tubes | Gr6 | SA333 |

| Baffles | Gr316L | SA240 |

Tubes / Tubesheet connection: welding and expansion

Welding procedures: EN ISO 15614-1 or EN 288.3

Welders certifications: According to EN 287.1 or EN 1418

Semi-automatic MIG/MAG processes

Quality Specificities:

Shell & Tube Heat Exchanger individually inspected according to the reception modula G, followed-up and validated by a Notified Body

3D view :