Thermal Specificities:

Quiri, as a specialist of heat exchangers, can provide you a condensate reheater / vapour condenser

Equipment delivered in England in 2018, as part of the manufacturing of a waste facility combined with a power plant.

The project will be able to generate up to 43MW per year of electricity from the incineration of household waste for the region and provide steam for a paper mill.

The condensate reheater supplied by Quiri is part of a set of 4 heat exchangers: two condensate reheaters, one feedwater heater and one dearator vapour condenser.

The function of these shell & Tubes exchangers is to reheat condensates from the steam coming from the upstream turbine.

The heat exchanger, of Quiri thermal design, condenses the steam with an integrated sub-cooling system of the condensed steam.

Some Technical Data :

| Shell Side | Tube Side | ||||

| Nature of the fluids | Steam / Gas 2 | Water / Liquid 2 | |||

| Number of passes | 1 | 4 | |||

| Service Temperature (inlet / outlet) | °C | 81.56

(Saturation) |

48 | 43.4 | 75.6 |

| Service Pressure | Bar (a) | 0.5 | 20.5 | ||

| Main Dimensions | |||||

| Power | MW | 10.5 | |||

| Exchanged Area Installed | m² | 392 | |||

| Bundle tubes Type | Bended U-tubes | ||||

| Shell Diameter | mm | 1000 | |||

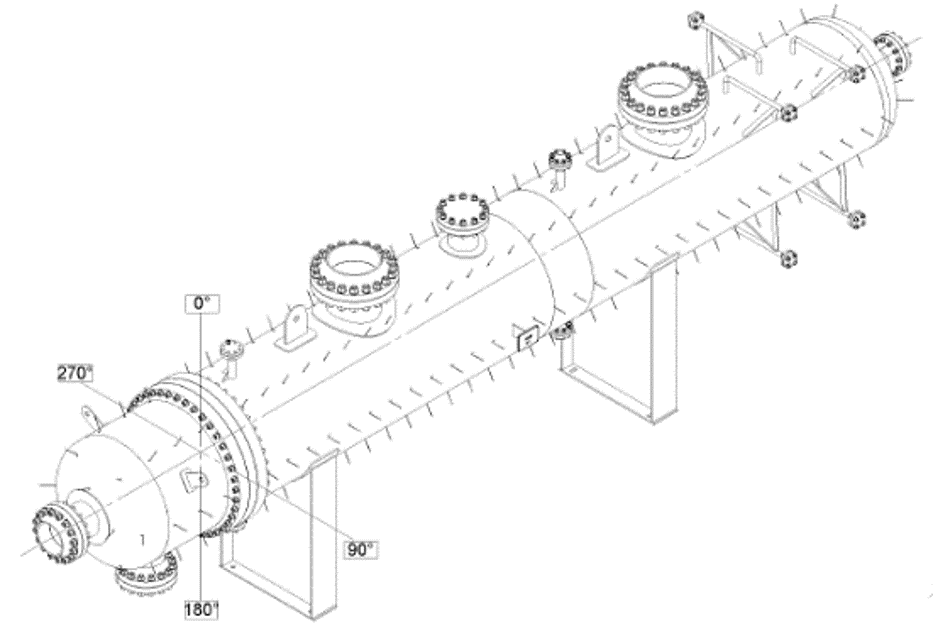

Geometric Specificities :

Horizontal tubular heat exchanger, overall length 8500 mm, empty weight 10 Tons.

Shell & Tube Exchanger , type BXU – with removable head and bundle

Construction Specificities:

Code : EN 13445

Regulation: DESP 2014/68/UE

Calculation temperature: -10°C /150°C tube side and shell side

Design pressures: -1/ +.30 bar (g) tube side and shell side

Test pressures: 44 bar (g) tube side and shell side

Risk category IV, reception modula G

Welding coefficient 0.85

Metallurgy :

| Material | Norm | |

| Shell | P265 GH | EN 10028-2 |

| Tubesheets | P355 QH | EN 10222-2 |

| Flanges | P355 QH | EN 10222-2 |

| Head | P265 GH | EN 10028-2 |

| Bundle tubes | 1.4404 | EN 10216-5 |

| Tubes | Gr6 | ASTM A333 |

| Baffles | S235JRG2 | EN 10025 |

Tubes / Tubesheet connection: welding and expansion

Welding procedures: EN ISO 15614-1 or EN 288.3

Welders certifications: According to EN 287.1 or EN 1418

Semi-automatic MIG/MAG processes

Quality Specificities:

Quality Plan according to client specifications, to the requirements of European and local regulations.

Data log book in English.

Equipment installed in England; the CDM (Construction Design and Maintenance) Regulations 2015 were applicable to the project.

Employees trained and approved for CDM 2015

3D view :