OIL COOLER – THERMAL SPECIFICITIES:

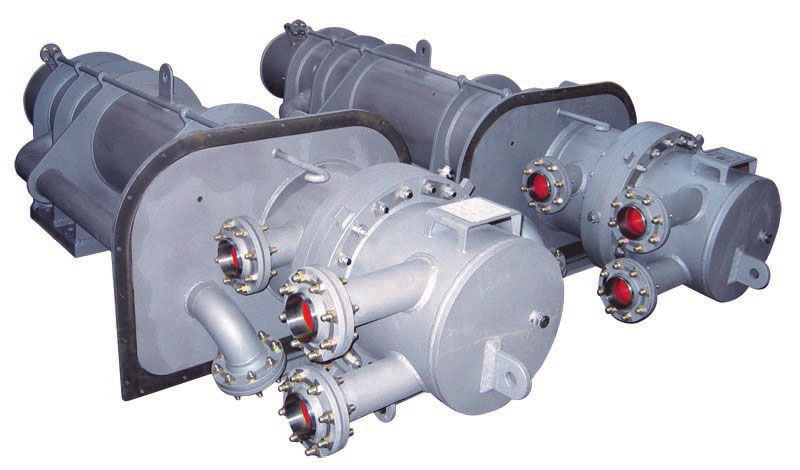

Quiri, specialist in shell and tube heat exchangers, introduces you a BEU TEMA type oil cooler.

We have delivered this type of heat exchangers for oil cooling to Finland, France and China as part of the construction of EPR type nuclear power plants.

The industrial oil cooler, which is a multitubular heat exchanger, of Quiri thermal design, provides cooling of the upper bearing oil of each motor (primary fluid) by heat exchange with circulating demineralized water (secondary fluid).

Some Technical Data:

| Shell side | Tube side | |||

| Nature of fluids | Oil | demineralized water | ||

| Flow | t/h | 55 | 60 | |

| Inlet temperature | °C | 53 | 38 | |

| Outlet temperature | °C | 44 | 42 | |

| Operating pressure | Bar abs | 2,5 | 8 | |

| Design pressure | Bar g | 10 | 13,5 | |

| Design temperature | °C | 95 | 95 | |

| Heat exchanged | kW | 260 | ||

| Main dimensions | ||||

| Type of bundle tubes | Bent finned tubes | |||

| Shell diameter | mm | 500 | ||

GEOMETRIC SPECIFICITIES:

Vertical tubular heat exchanger, overall length 3.5 m, empty weight 2 tons.

CONSTRUCTION SPECIFICITIES:

Code : EN 13445

Calculation of the heat exchanger by finite element. The heat exchanger shell and tube oil cooler is designed to withstand the seismic forces generated by horizontal and vertical accelerations as well as to withstand the seismic forces exerted in the event of primary piping failure.

Regulation: DESP 2014/68 / EU

METALLURGY:

| Material | Standard | |

| Shell | P265 GH | EN 10028-2 |

| Tubesheet | P295 GH | EN 10222-2 |

| Shell and channel flanges | P295 GH | EN 10222-2 |

| Cover | P295 GH | EN 10028-2 |

| Bundle tubes | Cu-DHP R220 | EN 12452 |

| Nozzles | P235 GH | EN 10216-2 |

| Baffles | P265 GH | EN 10028-2 |

Tube to tubesheet attachment : expanded 2 rills

Welding procedures : according to EN ISO 15614-1 or EN 288.3 and EN ISO 15613

Welders qualifications : according to EN ISO 9606-1 and EN 14732

QUALITY SPECIFICITIES:

LOFC according to customer specifications, requirements of European and local regulations.

The specific EDF, Stück and Chinese requirements were followed.

The project was followed by various organizations such as AREVA, Ceidre, TVO, Stück.

Learn more about our shell and tube oil coolers

As an expert in the design and manufacture of shell and tube heat exchangers, Quiri Thermal Exchanges offers state-of-the-art industrial oil coolers that are meticulously designed to cater to the diverse needs of various sectors. Engineered for optimal thermal efficiency, our heat exchangers for oil cooling are perfectly adapted to any industrial process that demands precise temperature control. Their robust tubular construction ensures reliability and longevity, even in the most demanding industrial environments, and allows our shell and tube oil coolers to deliver superior heat transfer capabilities. Our range of industrial tubular oil coolers is therefore synonymous with exceptional performance and reliability in critical cooling applications. For a seamless fit and optimized performance within your unique application, our oil coolers can also be tailored to your exact specifications.

For further details on our shell and tube heat exchangers for oil cooling, please do not hesitate to reach out to our dedicated team.