Technical specifications:

Quiri, specialist in heat exchangers, offers you a Proof Ring.

Spare part delivered in North Africa on behalf of a joint venture exploiting gas in the Algerian desert.

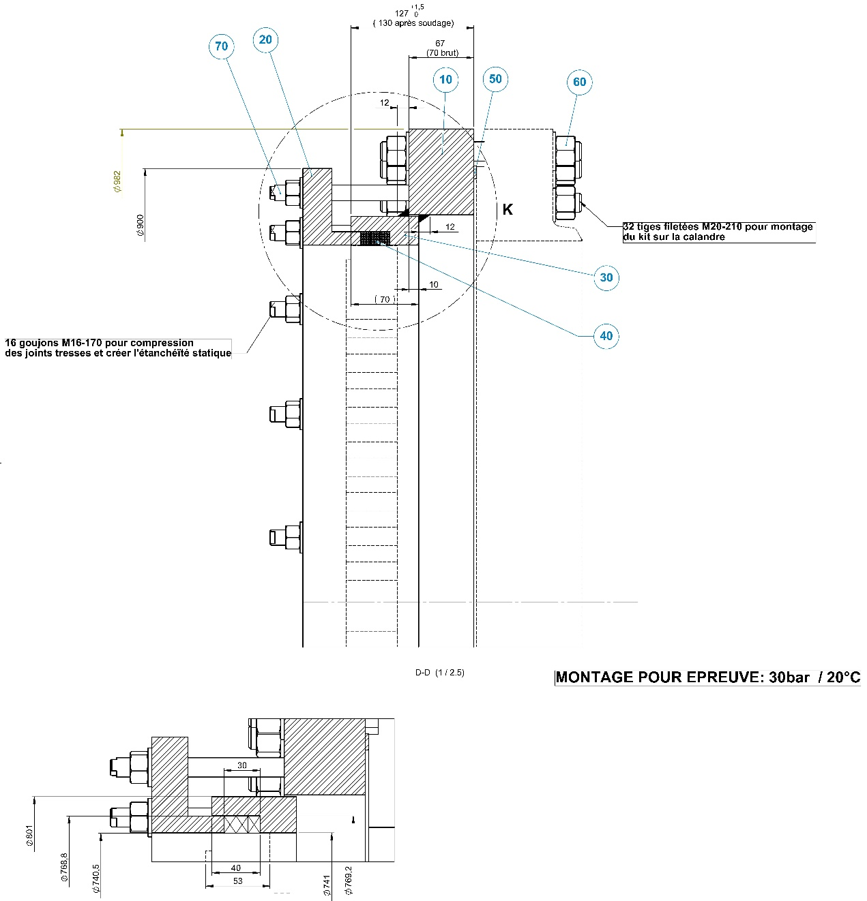

This hydraulic test ring was manufactured by Quiri for a tubular heat exchanger with floating head, type TEMA AES. This device is an indispensable tool for checking the tightness of the tube connection on the floating tube plate. The test ring is necessary to carry out the ten-year hydraulic test in the presence of the authorized inspector.

Technical datas

| Shell side | Tube side | ||

| medium | Huile stabilisée | Huile de Stripper | |

| Number of passes | 1 | 2 | |

| Service temperatures | °C | 191,7 / 173,5 | 86,2 / 100,5 |

| Service pressure | Bar G | 10,8 | 12,9 |

| Main dimension | |||

| Heat load | kW | – | |

| Installed exchange surface | m² | – | |

| Tube type | |||

| Channel diameter | mm | 750 | |

Geometrical specifities :

Test ring for horizontal heat exchanger.

Construction :

Code : ASME VIII div 1

Country rules : Algérian

Design temperature : +240 °C shell side / +150 °C tube side

Design pressure : 14 bars (g) shell side / 20 bars (g) tube side

Test pressure : 21 bars (g) shell side et 30 bars (g) tube side

Welding joint : 0.85

Main material :

| grade | standard | |

| Test flange | P265GH | EN 10028-2 |

| Flat end cover | P265GH | EN 10028-2 |

| Gasket positionning flange | P265GH | EN 10028-2 |

Welding : acc to ASME IX

Welders qualification : acc to ASME IX

2D view :