Thermal specificities:

Quiri, specialist in heat exchangers, introduces you a buffer tank.

The buffer tank supplied by Quiri is part of a set of 4 heat exchangers: vaporizer, tank and 2 sub-coolers.

The project consists of the construction of a cogeneration plant running on biomass and supplying heat in the form of steam and hot water to 2 industrialists near the site.

The vaporizer is powered by steam drawn from the turbine and will produce steam for industrial use.

The primary condensates (steam turbine) will be returned to the boiler feed tank.

The secondary condensates come from the industrial.

The function of this tank, designed by Quiri, is to keep a certain volume of liquid water in order to guarantee the presence of liquid in the sub-coolers. This tank is also used for regulation on the primary side.

Some Technical Data:

| Shell side | ||

| Nature of fluids | condensates | |

| Operating temperature | °C | 215 |

| Operating pressure | Bar abs | 25 |

| Design pressure | Bar g | 45 |

| Design temperature | °C | 290 |

| Shell diameter | mm | 600 |

Geometric specificities:

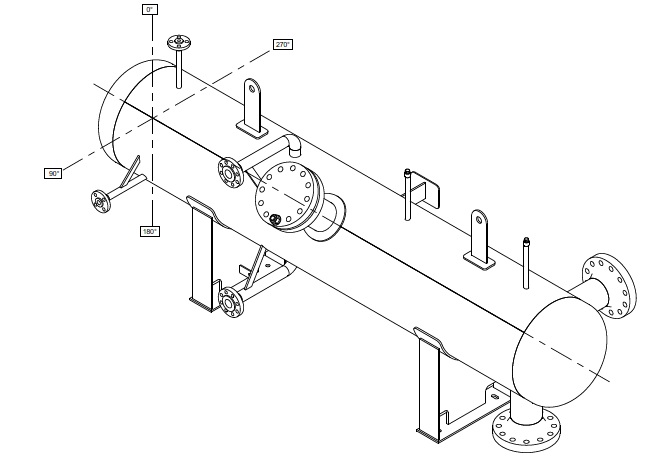

Horizontal tank, overall length 3,3 m, empty weight 1,2 tons.

Construction Specificities:

Code : CODAP

Regulation: PED 2014/68 / EU

Risk category IV, reception module G

Joint efficiency : 0.85

Metallurgy:

| Material | Standard | |

| Shell | P265 GH | EN 10028-2 |

| Cover | P265 GH | EN 10028-2 |

| Nozzles | Gr6 | SA333 |

Welding procedures : according to EN ISO 15614-1 or EN 288.3 and EN ISO 15613

Welders qualifications : according to EN ISO 9606-1 and EN 14732

Quality specificities :

LOFC according to customer specifications, requirements of European and local regulations.

3D view:

Quiri, spécialiste des réservoirs sous pression & échangeurs thermiques

Spécialiste de la conception et la fabrication d’échangeurs thermiques tubulaires, Quiri propose une vaste gamme d’équipements et réservoirs sous pression. Nos compétences de pointe en chaudronnerie industrielle nous permettent de développer tous types d’appareils à pression, en acier ou en inox : séparateur, réservoir tampon ou encore amortisseur de pulsations. Nos experts sont par ailleurs en mesure de développer votre réservoir à pression sur mesure, selon votre cahier des charges spécifique et les codes de construction en vigueur. Toutes les précautions nécessaires sont prises pour vous livrer un équipement sous pression fiable, durable, conforme aux exigences réglementaires et pouvant ainsi être exploité en toute sécurité. Pour assurer la fiabilité de l’appareil sous pression, différents contrôles sont réalisés tout au long du cycle de vie de l’équipement, de sa fabrication jusqu’à l’exploitation. Pour échanger au sujet de votre projet de réservoir sous pression ou obtenir davantage d’informations à propos de nos échangeurs de chaleur industriels, n’hésitez pas à contacter nos experts.