Technical specifications:

In a process of nitrogen and oxygen production, by multi-stage compression, our customer Burckhardt Compression asks us for pulsation dampers. Indeed, such an installation including different stages of compression, generates shock waves that affect the performance and efficiency as well as the mechanical strength of the entire installation, including the instrumentation and piping. At each pressure level, it is necessary to provide a device to dampen and reduce the amplitude of the waves propagating at the discharge of the compression stage. This equipment must be calculated taking into account permanent pulsations in a range of plus or minus 5% of the working pressures. Made of materials compatible with the fluids and the temperature and pressure conditions, in carbon steel, the devices must necessarily be built according to the CODAP and comply with the European Pressure Equipment Directive.

Some technical datas :

| Name of item | Pulsation Damper 1st stage suction | Pulsation Damper 3rd stage discharge | Pulsation Damper 1st stage suction | Pulsation Damper 2nd stage discharge |

| Item identification number | DAMP 701 | DAMP 706 | DAMP 601 | DAMP 604 |

| Medium

|

NITROGEN DRY | NITROGEN DRY | OXYGEN DRY | OXYGEN DRY |

| operating pressure | 5 bar | 38 bar | 8 bar | 35 bar |

| Design pressure | 6 bar | 43 bar | 9 bar | 38 bar |

| Hydrotest pressure | 9 bar | 64,5 bar | 13,5 bar | 57 bar |

| Design temperature | 100 / (-28,9) | 200 / (-28,9) | 100 / (-28,9) | 180 / (-28,9) |

| Welding efficiency | 0,85 | 0,85 | 0,85 | 0,85 |

| Corrosion allowance | 1,6 | 1,6 | 1,6 | 1,6 |

| volume | 750 l | 160 l | 200 l | 160 l |

| code | CODAP | CODAP | CODAP | CODAP |

| Material grade | ||||

| Shell | P 265 GH EN 10 028-2 | A333 GR 6 | A333 GR 6 | A333 GR 6 |

| Nozzles | A333 GR 6 | A333 GR 6 | A333 GR 6 | A333 GR 6 |

| Nozzle flanges | BF 42 F | BF 42 F | BF 42 F | BF 42 F |

| supports | P 265 GH EN 10 028-2 | P 265 GH EN 10 028-2 | P 265 GH EN 10 028-2 | P 265 GH EN 10 028-2 |

| Shell dishes | P 265 GH EN 10 028-2 | A 420 WPL6 | A 420 WPL6 | A 420 WPL6 |

| Gaskets | AFM 34 | AFM 34 | SIGRAFLEX Typ V20010C2 | SIGRAFLEX Typ V20010C2 |

| Reinforcement pads | P 265 GH EN 10 028-2 | P 265 GH EN 10 028-2 | P 265 GH EN 10 028-2 | P 265 GH EN 10 028-2 |

Geometric Specificities :

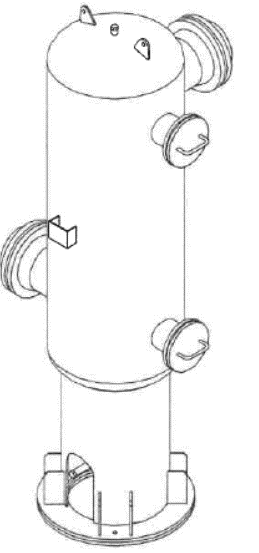

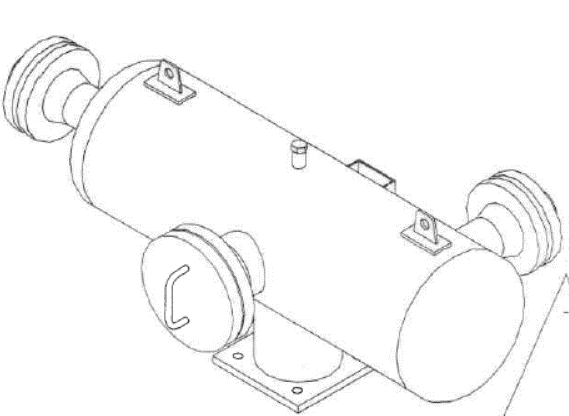

Vertical (suction) and horizontal (discharge) shock absorbers, with hand hole type inspection holes.

Constructive Specificities :

Code : CODAP

Regulation: DESP 97/23/EC

Design temperature: 80°C / +150 °C

Welding coefficient 0.85

Welding processes: EN 288.3 approved

Welders’ approvals: According to EN 287.1

Semi-automatic MIG/MAG processes

Quality Specificities :

LOFC according to customer and local specifications.

operating file in English and French language

Suction

Discharge

Quiri, spécialiste des réservoirs sous pression & échangeurs thermiques

Spécialiste de la conception et la fabrication d’échangeurs thermiques tubulaires, Quiri propose une vaste gamme d’équipements et réservoirs sous pression. Nos compétences de pointe en chaudronnerie industrielle nous permettent de développer tous types d’appareils à pression, en acier ou en inox : séparateur, réservoir tampon ou encore amortisseur de pulsations. Nos experts sont par ailleurs en mesure de développer votre réservoir à pression sur mesure, selon votre cahier des charges spécifique et les codes de construction en vigueur. Toutes les précautions nécessaires sont prises pour vous livrer un équipement sous pression fiable, durable, conforme aux exigences réglementaires et pouvant ainsi être exploité en toute sécurité. Pour assurer la fiabilité de l’appareil sous pression, différents contrôles sont réalisés tout au long du cycle de vie de l’équipement, de sa fabrication jusqu’à l’exploitation. Pour échanger au sujet de votre projet de réservoir sous pression ou obtenir davantage d’informations à propos de nos échangeurs de chaleur industriels, n’hésitez pas à contacter nos experts.