Quiri, spécialiste des échangeurs thermiques, vous propose un système intégrant évaporateur et condenseur frigorifique.

Spécificités Thermiques :

Le projet global de ce condenseur / évaporateur frigorifique consiste à rénover les unités existantes de production d’eau glacée embarquées sur 4 frégates de marine militaire. Ces navires sont chacun équipés de 4 installations devant produire de l’eau glacée à raison de 57,4 m3/h à 6 °C au départ du réseau, avec une température de retour à 12 °C. Le fluide frigorigène utilisé dans ces échangeurs thermiques était le R 11, fluide qui n’est plus autorisé et le frigoriste préconise le R134 A. La condensation du frigorigène se fait avec de l’eau de mer, dont la température peut atteindre sous certaines latitudes 32 °C, valeur retenue pour le design thermique.

Outre les performances thermiques, les enjeux consistent de proposer des Échangeurs Multitubulaires compacts respectant les encombrements existants, et capables de fonctionner avec de l’eau de mer.

L’impératif de compacité exige d’intégrer en une enceinte sous pression à la fois le condenseur et l’évaporateur. Cette contrainte requiert l’aménagement d’un séparateur afin d’éviter la présence de frigorigène liquide à l’aspiration du compresseur, mais aussi de concevoir une enceinte à pression susceptible de contenir des faisceaux de tubes fonctionnant en haute pression (HP, condenseur) et un autre en basse pression (BP, évaporateur).

Quelques Données Techniques :

Thermal Specifics :

The global project consists in renovating the existing chilled water production units embarked on 4 naval frigates. These ships are each equipped with 4 installations to produce chilled water at a rate of 57.4 m3/h at 6°C from the network, with a return temperature of 12°C. The refrigerant used in these heat exchangers was R11, a fluid that is no longer authorized and the refrigerator manufacturer recommends R134 A. The refrigerant is condensed with sea water, which at certain latitudes can reach a temperature of 32 °C, the value used for the thermal design.In addition to the thermal performance, the challenge is to offer compact multi-tube heat exchangers that respect the existing dimensions and are able to operate with sea water.The need for compactness requires the integration of both the condenser and the evaporator in a pressure vessel. This constraint requires the installation of a separator in order to avoid the presence of liquid refrigerant at the compressor suction, but also to design a pressure vessel capable of containing bundles of tubes operating at high pressure (HP, condenser) and another at low pressure (LP, evaporator).Quelques Données Techniques :

Geometric Specificities :

Horizontal tubular heat exchanger, Type 2 in 1

Constructive Specificities :

Code : AD MerkblätterRegulation: Germanischer LloydDesign temperature: -10°C / +66 °CCalculation pressures: -1/ 16 bar (g) on channel side and shell sideTest pressures: 44 bar (g) on channel side and shell side.Welding coefficient 0.85

Material grade :

Tube to tubesheet attachments: welded and expandedWelding processes: EN ISO 15614-1 or EN 288.3 approvedWelders’ approvals: According to EN 287.1 or EN 1418Semi-automatic MIG/MAG processes

Quality Specificities :LOFC according to customer specifications, requirements of European and local regulations.Operating file in English and German languageGermanischer Lloyd-certified design and manufacture

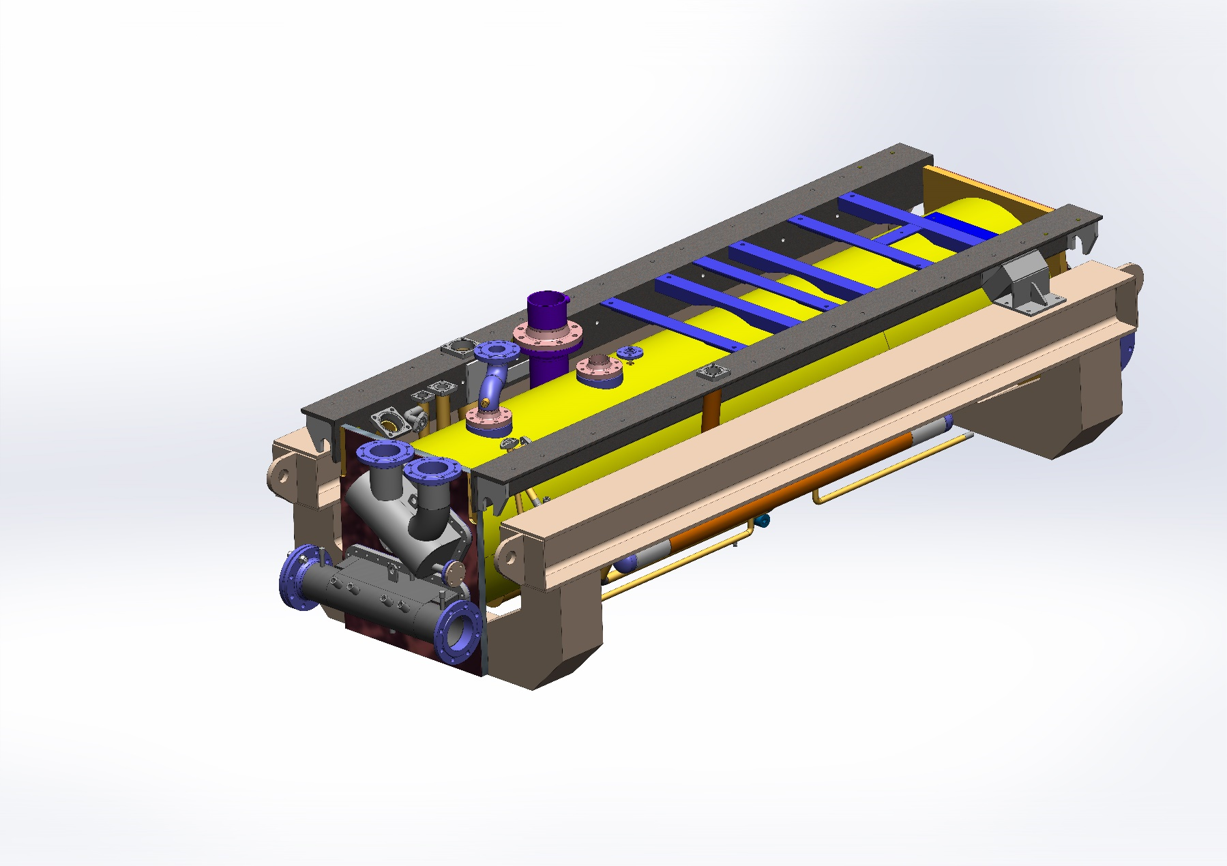

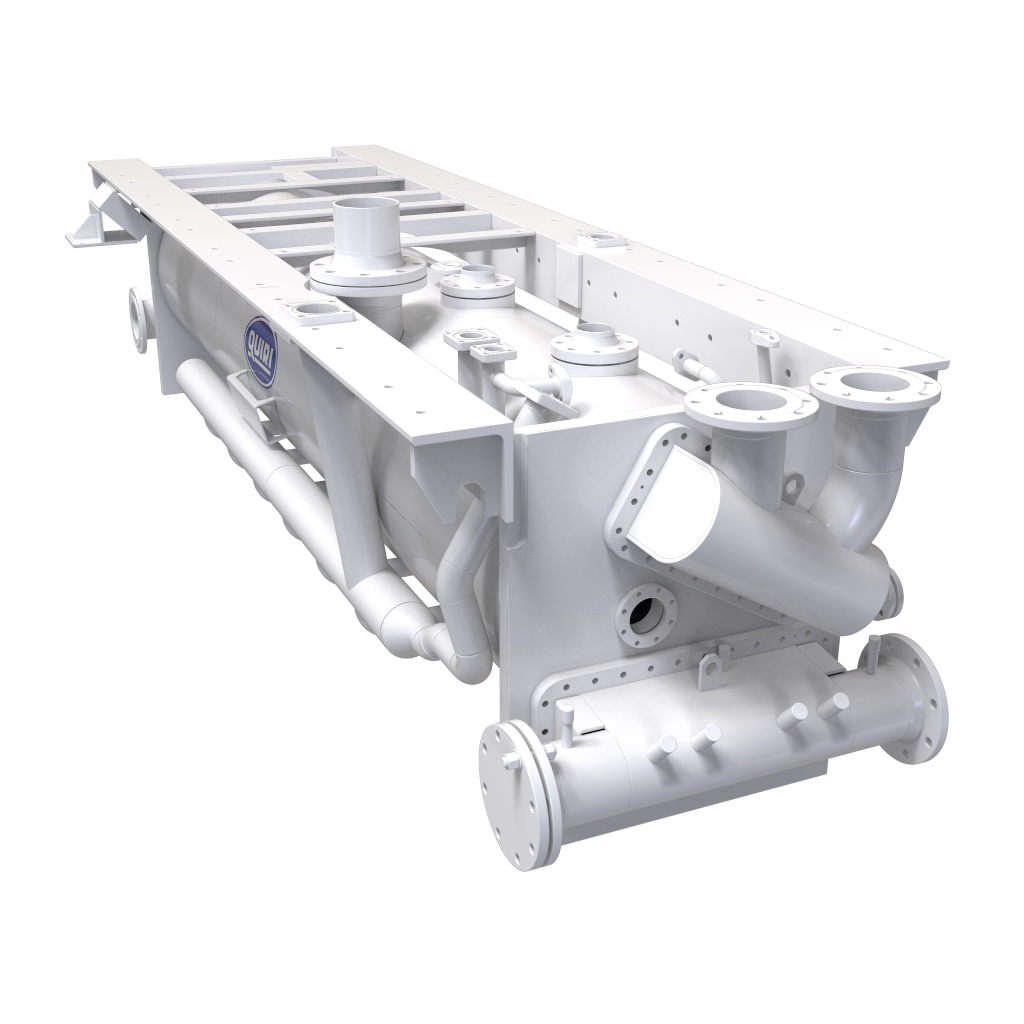

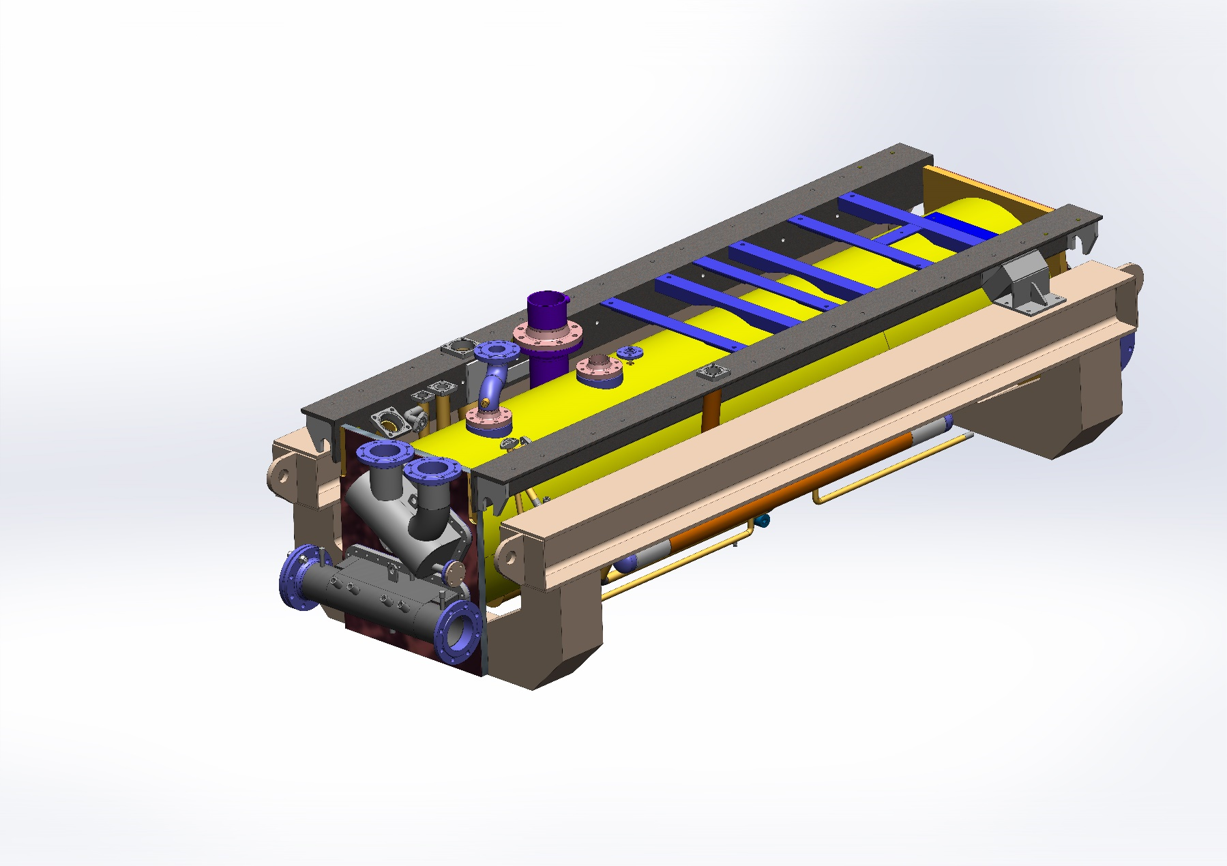

Vue 3D :

| Evaporator | Chilled water production | Condenser | Cooling fluid | ||||

| Fluid names | R134 A | water | R134A | Sea water | |||

| Number of passes | 1 | 2 | 1 | 2 | |||

| operating Temperature (inlet / outlet) | °C | 4 (saturation) | 12 / 6 | 55 /41.7 (saturation) | 43.4 | 75.6 | |

| operating pressure | Bar (a) | 3.36 | 6 | 10.2 | 3 | ||

| Heat exchange area | M² | 123.4 | 75.3 | ||||

| Duty | kW | 400 | 530 | ||||

| Type of bundle tubes | Copper low fin tubes | Titanium low fin tubes with internal enhancement | |||||

| grade | standard | ||||||

| shell | P265 GH | EN 10028-2 | |||||

| tubesheet | P265 GH + titane | ||||||

| Channel flanges | P265 GH | EN 10028-2 | |||||

| Dishes | P265 GH | EN 10028-2 | |||||

| Bundle tubes | Cuivre et titane | DIN 1781 +DIN 17671 | |||||

| Nozzles | Gr6 | ASTM A333 | |||||

| Baffles | S235JRG2 | EN 10025 | |||||

| Evaporateur | Production eau glacée | Condenseur | Fluide de refroidissement | ||||

| Nature des fluides | R134 A | Eau | R134A | Eau de mer | |||

| Nombre de passes | 1 | 2 | 1 | 2 | |||

| Températures service (entrée / sortie) | °C | 4 (saturation) | 12 / 6 | 55 /41.7 (saturation) | 43.4 | 75.6 | |

| Pressions service | Bar (a) | 3.36 | 6 | 10.2 | 3 | ||

| Surface d’échange | M² | 123.4 | 75.3 | ||||

| Puissance | kW | 400 | 530 | ||||

| Type de tubes faisceau | Cuivre à ailettes basses extérieures | Titane à ailettes basses extérieures et rainures intérieures | |||||

Spécificités Géométriques :

Échangeur thermique tubulaire horizontal, Type 2 en 1

Spécificités Constructives :

Code : AD Merkblätter

Règlementation : Germanischer Lloyd

Température de calcul : -10°C / +66 °C

Pressions de calcul : -1/ 16 bar (g) coté boite et coté calandre

Pressions d’épreuve : 44 bar (g) coté boite et coté calandre

Coefficient de soudure 0.85

Métallurgie :

| Matière | Norme | |

| Calandre | P265 GH | EN 10028-2 |

| Plaques tubulaires | P265 GH + titane | |

| Brides de boites | P265 GH | EN 10028-2 |

| Fond | P265 GH | EN 10028-2 |

| Tubes de faisceau | Cuivre et titane | DIN 1781 +DIN 17671 |

| Tubulures | Gr6 | ASTM A333 |

| Chicanes | S235JRG2 | EN 10025 |

Liaison tube/ plaque : soudage et dudgeonnage

Procédés de soudage : Homologués EN ISO 15614-1 ou EN 288.3

Agréments des soudeurs : Suivant EN 287.1 ou EN 1418

Procédés semi-automatique MIG/MAG

Spécificités Qualités :

LOFC selon les spécifications clients, les exigences des réglementations européennes et locales.

Dossier d’exploitation en langue anglaise et allemande

Conception et fabrication ayant fait l’objet d’une certification Germanischer Lloyd

Vue 3D de l’évaporateur-condenseur frigorifique :