Thermal Specifics :

Within the framework of the rehabilitation of a Thermal Power Plant in North Africa under the management of an Algerian Electricity producer, Quiri, specialist in heat exchangers, realized the mechanical design and manufacturing of a high pressure feedwater heater RHP.

The function of this vertical type heat exchanger is to heat the feed water which circulates on the tube side and then deliver it into the steam generator. The reheating steam circulating shell side is taken from the medium-pressure casing of the turbine.

Quiri supplied two identical reheaters for two different lines.

This reheater is a multitubular heat exchanger characterized by a so-called three-in-one system (desuperheating, cooling and subcooling of the steam shell side).

Quelques Données Techniques :

| Shell Side | Tube side | |||

| Medium | Stream / condensate | Feed water | ||

| Flow | Kg/h | 19 996 / 31 523 | 520 300 | |

| Inlet temperature | °C | 477 / 218,64 | 189 | |

| Outlet temperature | °C | / 194,56 | 213,14 | |

| Design pressure | Kg/cm² | 26 | 250 | |

| Hydrotest pressure | Kg/cm² | 39 | 375 | |

| Design temperature | °C | 490 / 230 | 250 | |

| Number of passes | 1 | 2 | ||

| Main dimension | ||||

| Installed heat exchange surface | m² | 574,2 | ||

| Tube type | Bent bare tubes | |||

| Shell diameter | mm | 1182 | ||

Geometric Specificities :

Vertical heat exchanger ; Empty weight 21 Tons.

Constructive Specificities :

Code : ASME VIII div 1 Ed. 2015 + TEMA 9ème édition

Country rules : PED 2014/68/UE et Réglementation Algérienne : Décret No. 90/245 relatif à la réglementation Algérienne des appareils à pression de Gaz et Décret No. 90/246 relatif à la réglementation Algérienne des appareils à pression de Vapeur

Welding joint UW-12 (FULL) shell side and tube side

Main materials :

| grade | standard | |

| Skirt shell | 13CrMo4 | EN 10028-3 |

| Shell | SA516 Gr 70 | ASME |

| Tubesheet | SA266 Cl 2 | ASME |

| Desuperheating baffles | 13CrMo4 | EN 10028-3 |

| Sub cooling baffles | S235 JRG2 | EN 10205 |

| tubes | P265GH TC2 | EN 10216-2 |

| Forged nozzles | Gr6 | ASTM A333 |

| Baffles | SA350 LF2 | ASME |

tube/ tube sheet attachment : welding and expansion

Welding : acc to ASME IX

Welders qualification : acc to ASME IX

Quality Specificities :

Quality plan according to customer specifications, European and Algerian regulations requirements.

Establishment of a preliminary file and sending it to the Algerian General Directorate of Mines (DGM), formerly called DDP and ARH for approval before launching the manufacturing process.

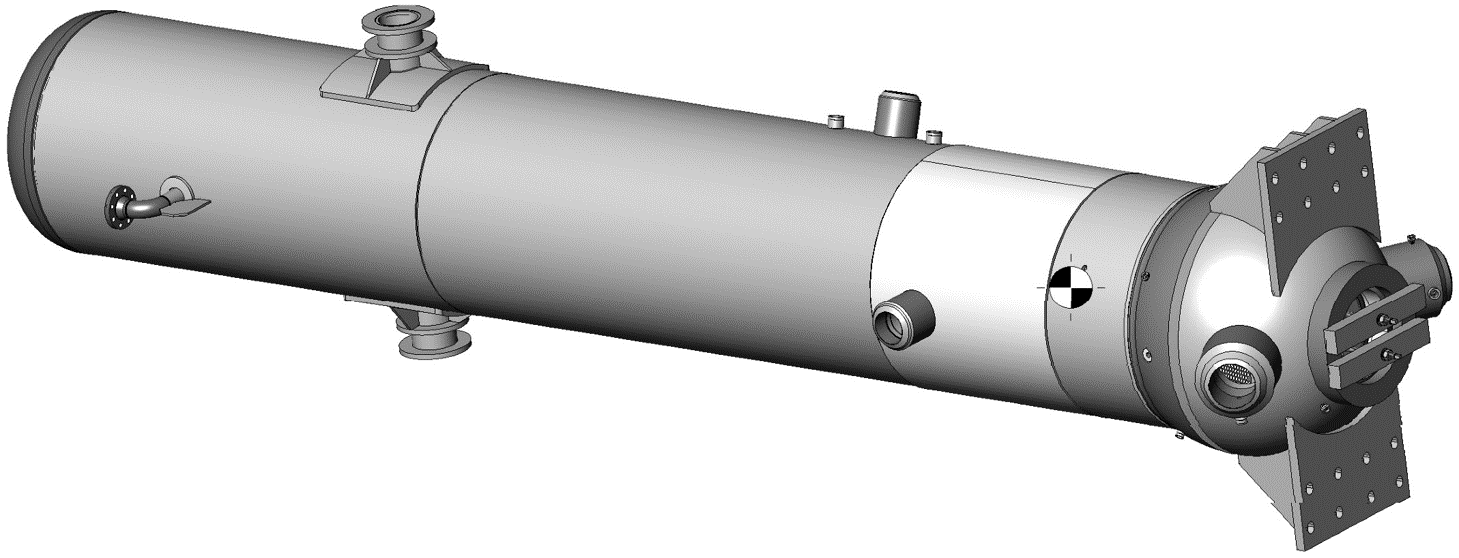

3D VIEW :