Thermal Specificities

Quiri, as a specialist of heat exchangers, can provide you a spare tube bundle.

Equipment delivered in France in 2019 on behalf of a company specialised in the manufacturing of chemicals derived from chloride.

This tube bundle is a spare part for an exchanger in operation in the customer’s factory.

The shell & Tube heat exchanger is a process heat exchanger used to cool vinyl chloride.

Technical Data of the heat exchanger:

| Shell Side | Tube Side | ||

| Nature of the fluids | Water / Liquid 2 | Vinyl Chloride / Gas 1 | |

| Number of passes | 1 | 4 | |

| Service Temperature (inlet / outlet) | °C | 25 | 20 |

| Service Pressure | Bar (a) | 3 | 12 |

| Main Dimensions | |||

| Power | kW | – | |

| Exchanged Area Installed | m² | – | |

| Bundle tubes Type | Straight Tubes | ||

| Shell Diameter | mm | 600 | |

Geometric specificities :

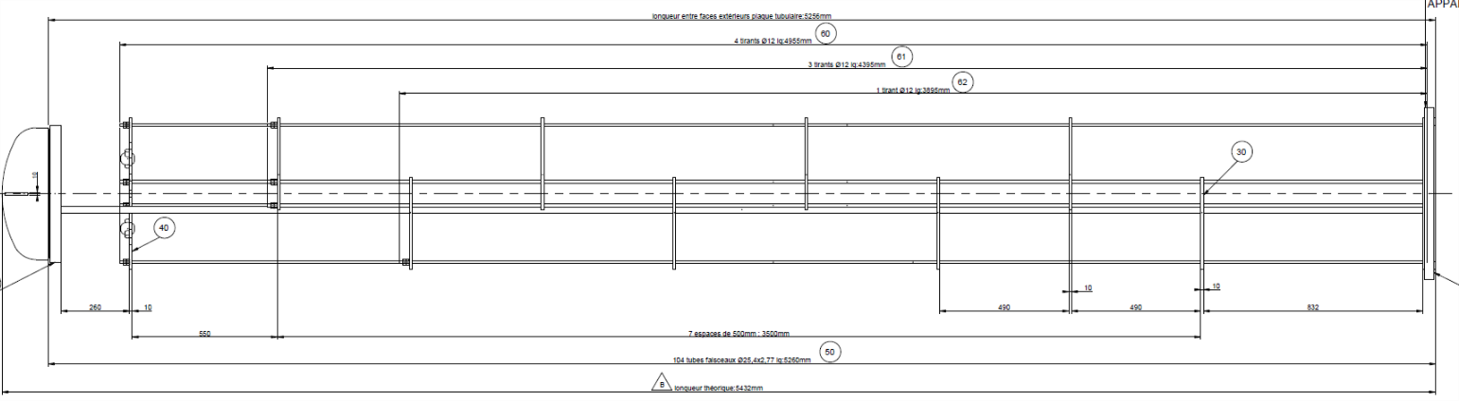

Spare Tube Bundle for horizontal shell & Tube heat exchanger, overall length 5400 mm, empty weight 1200 Kg.BEW TEMA type floating head tube bundle – fully removable .

Construction Specificities :

Code: CODAP

Regulation: DESP 2014/68 / EU / Decree of 20 November 2017

Calculation temperature: 0 ° C / + 50 ° C on the tubeside and 0 ° C / + 40 ° C on the shell side

Design pressures: 16 bar (g) on the tubeside and 6 bar (g) on the shell side

Test pressures: 23 bar (g) on the tubeside and 9 bar (g) on the grille side

Risk category IV, Inspection modula G

Welding coefficient 0.85

Metallurgy :

| Matière | Norme | |

| Calandre | Gr6 | SA333 |

| Plaques tubulaires | P280GH | EN 10222-2 |

| Calotte sphérique | P265GH | EN 10028-2 |

| Tubes de faisceau | P235GH – TC1 | EN 10216-2 |

| Chicanes | S235JRG2 | En 100025 |

Tube/ tubesheet connection : 2 passes welding with offset of 90° and light expansion after welding.

Welding procedures: EN ISO 15614-1 or EN 288.3

Welders certifications: According to EN 287.1 or EN 1418

Automatic processes under flux – TIG + Electrode – Processes 138 for parts subject to pressure,

Semi-automatic MIG / MAG processes for non-subject to pressure parts.

Quality Specificities:

Spare tube bundle inspection by a Notified Body without delivery of a CE marking (component considered as a spare part followed up during the operation according to the decree of march 15, 2000)

Manufacturing of a mock-up of tube / tubesheet assembly witnessed by the client and approved in the laboratory of the client.

2D View :