Technical specifications :

In various gas treatment or steam conditioning processes, the flows circulating at the inlet or outlet of heat exchangers are sometimes loaded with liquid or solid particles.

As an example, a common application consists in carrying out a first dehumidification step at the outlet of an air cooler. Indeed, by cooling atmospheric air (characterized by its relative humidity), a condensation of part of the vapour contained takes place. This condensed steam can be found in the form of droplets or mist depending on the flow regimes (separate phase, intermittent, dispersed,…) and the separation device must be able to collect the liquid phase on one side and allow the gas to continue its journey through the process. The separation can be done by devices such as cyclone or coalescing mats.

In other situations, if we take the case of a steam or refrigerant in a thermodynamic cycle, it is necessary to avoid dragging a liquid phase towards a compressor or a turbine. In these cases the separators can be of the coalescing mat or baffle type.

In all these applications, the pressure drop must be controlled for reasons of the overall performance of the installation.

Some technical data on wet air and dry steam applications:

| Name of item | Wet air cooler | LP separator |

| Fluid

|

Wet air | Saturated steam |

| upstream operating pressure | 21.45 bar | 3.2 bar a |

| percentage / liquid flow rate | 0.039 kg/s | 90% |

| Inlet temperature | 35 °C | saturation |

| After separation temperature | 35 °C | 175 °C |

| Gas flow rate/separated steam | 12.6 kg/s | 30 t/h |

| Pressure drop | 0.08 bar | 0.09 bar |

| Design pressure | 24 bar | -1/ 4.2 bar |

| Hydrotest pressure | 15 bar | 6 bar |

| Design temeprature | -10 / 120 °C | 0 / 250 °C |

| Welding befficiency | 0,7 | 0,85 |

| Corrosion allowance | 3 | 1.5 |

| Material | ||

| shell | P265 GH | P265 GH |

| Separator element | 304 L | 304L |

| nozzles | P235 GH -TC1 | P235 GH – TC1 |

Geometric Specificities :

Integrated in exchanger outlet box (wet air cooler) and vertical separator tank (superheated steam)

Constructive Specificities :

Code: ASME VIII (cooler) CODAP (superheated steam)

Regulation: DESP 97/23/EC

Welding Processes: ASME IX or EN 288-3 Approved

Welders’ approvals: According to ASME IX or EN 1418

Semi-automatic MIG/MAG processes

Quality Specificities:

LOFC according to customer and local specifications.

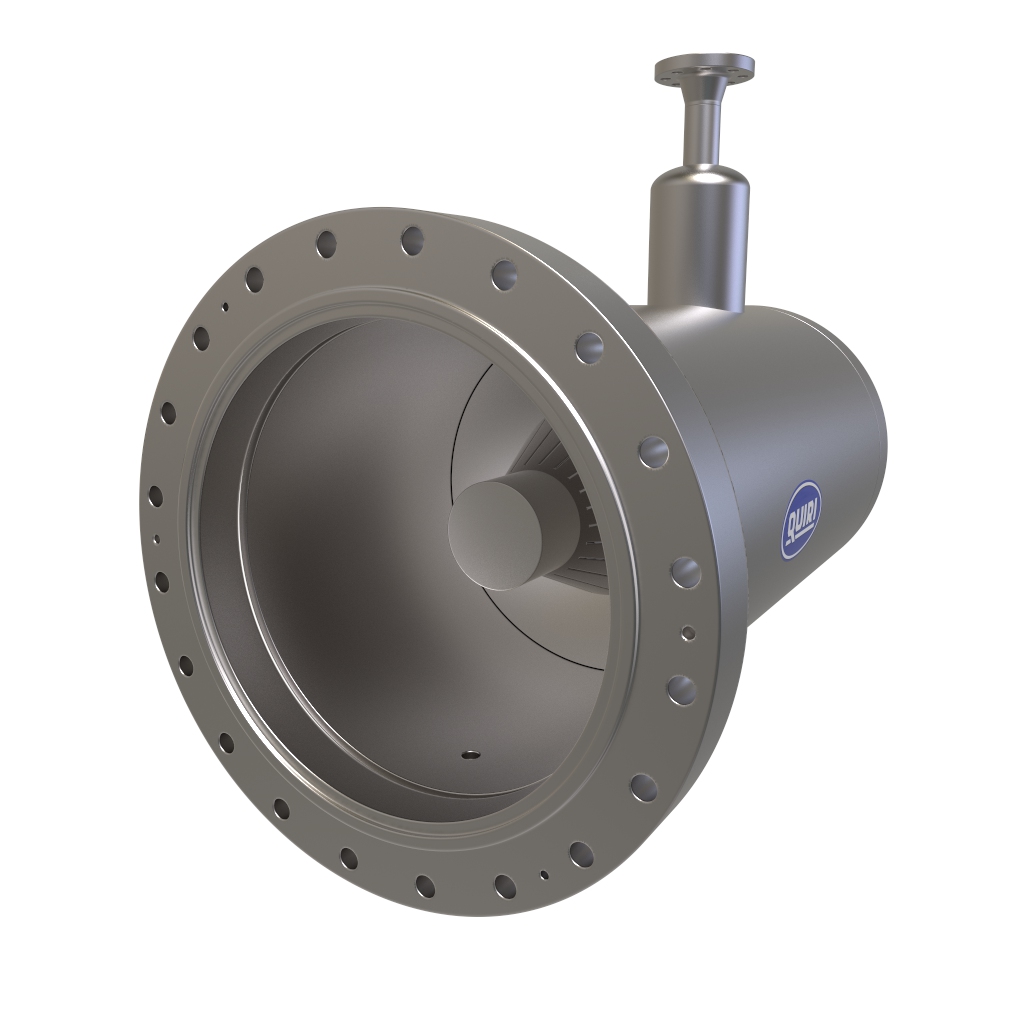

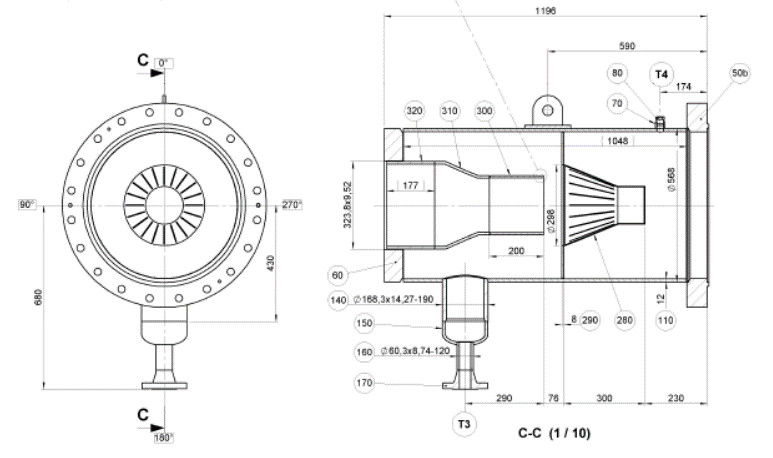

Séparateur cyclone

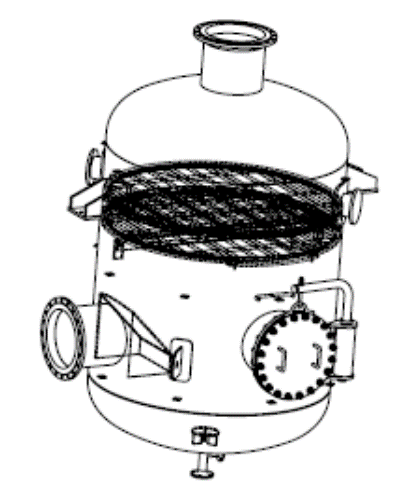

Séparateur vertical

Séparateur cyclone

Quiri, spécialiste des réservoirs sous pression & échangeurs thermiques

Spécialiste de la conception et la fabrication d’échangeurs thermiques tubulaires, Quiri propose une vaste gamme d’équipements et réservoirs sous pression. Nos compétences de pointe en chaudronnerie industrielle nous permettent de développer tous types d’appareils à pression, en acier ou en inox : séparateur, réservoir tampon ou encore amortisseur de pulsations. Nos experts sont par ailleurs en mesure de développer votre réservoir à pression sur mesure, selon votre cahier des charges spécifique et les codes de construction en vigueur. Toutes les précautions nécessaires sont prises pour vous livrer un équipement sous pression fiable, durable, conforme aux exigences réglementaires et pouvant ainsi être exploité en toute sécurité. Pour assurer la fiabilité de l’appareil sous pression, différents contrôles sont réalisés tout au long du cycle de vie de l’équipement, de sa fabrication jusqu’à l’exploitation. Pour échanger au sujet de votre projet de réservoir sous pression ou obtenir davantage d’informations à propos de nos échangeurs de chaleur industriels, n’hésitez pas à contacter nos experts.