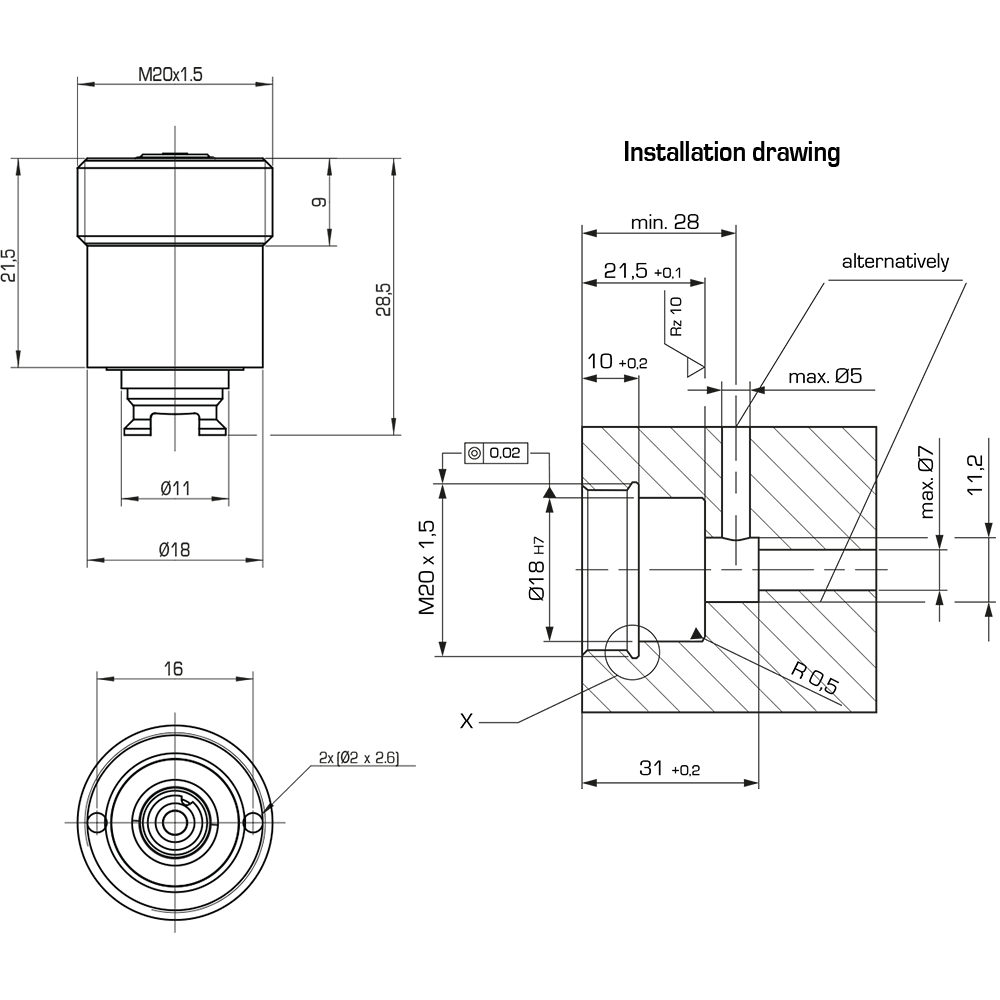

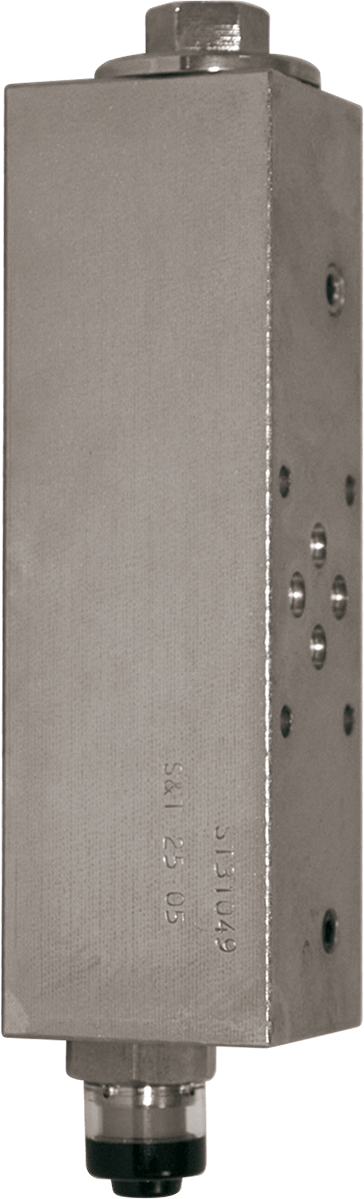

Self-Coupler M20x1.5

Screw-in coupling mechanism.

Operating pressure from 5 to 350 bar.

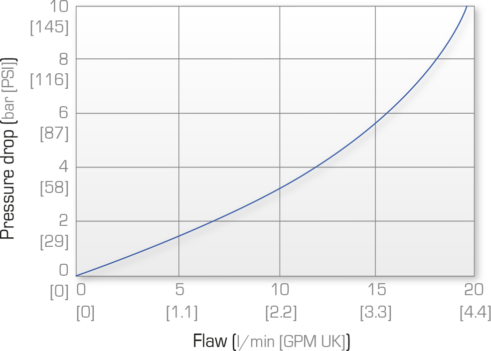

Flow 12l/min at 70 bar. Max flow 20l/min.

Description

The QUIRI Screw In Coupling Self-Coupler is specifically designed for industrial automations where our manufacturing connections can minimize costly downtime due to repair work or mold and tool changes. QUIRI self-couplings built into the manifolds enable rapid, simultaneous connection and disconnection of an unlimited number of lines for a wide variety of media. The unique patented design allows the fittings to be connected/disconnected under full working pressure. This coupling mechanism is made of steel and is suitable for hydraulic applications such as clamping and palletizing machines and automatic tool changing systems on machine tools.

Use

Couplings are used for loss-free transport of liquid or gaseous media. The system seal between coupling mechanism and coupling tip ensures axial sealing and is mounted in the coupling system. The couplings can mate under pressure up to the maximum pressure of 150 bar.

Maximum operating pressure is 350 bar (4351PSI)

Operating temperatures are between -30°C and +120°C (-6°F and +230°F)

In case of installation on circuits equipped with accumulator, the coupling end must be mounted with pressure reduction. In the uncoupled state, it maintains approximately 30 bars of any pressure in the return piping.

Features

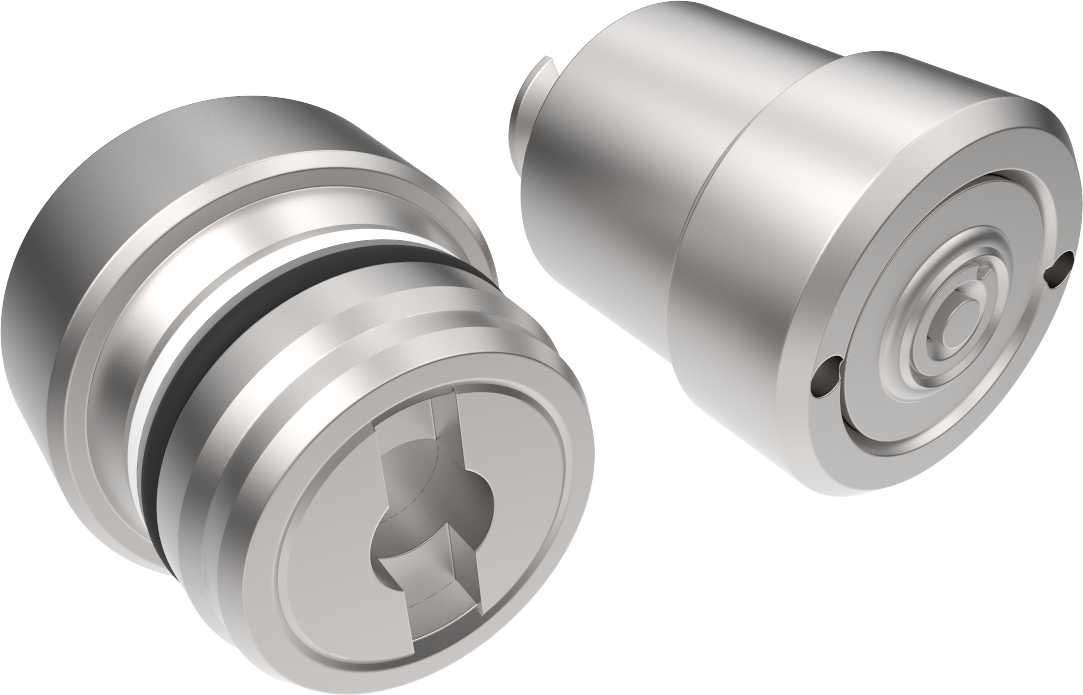

Before the coupling operation, the coupling mechanism and the coupling tip face each other in a coaxial position. The radial positioning tolerance must not be exceeded.

The coupling force due to the hydraulic pressure can be determined according to the formula: F [N] = 9.4 xp [bar], between tip and coupling mechanism must apply without slipping from the outside.

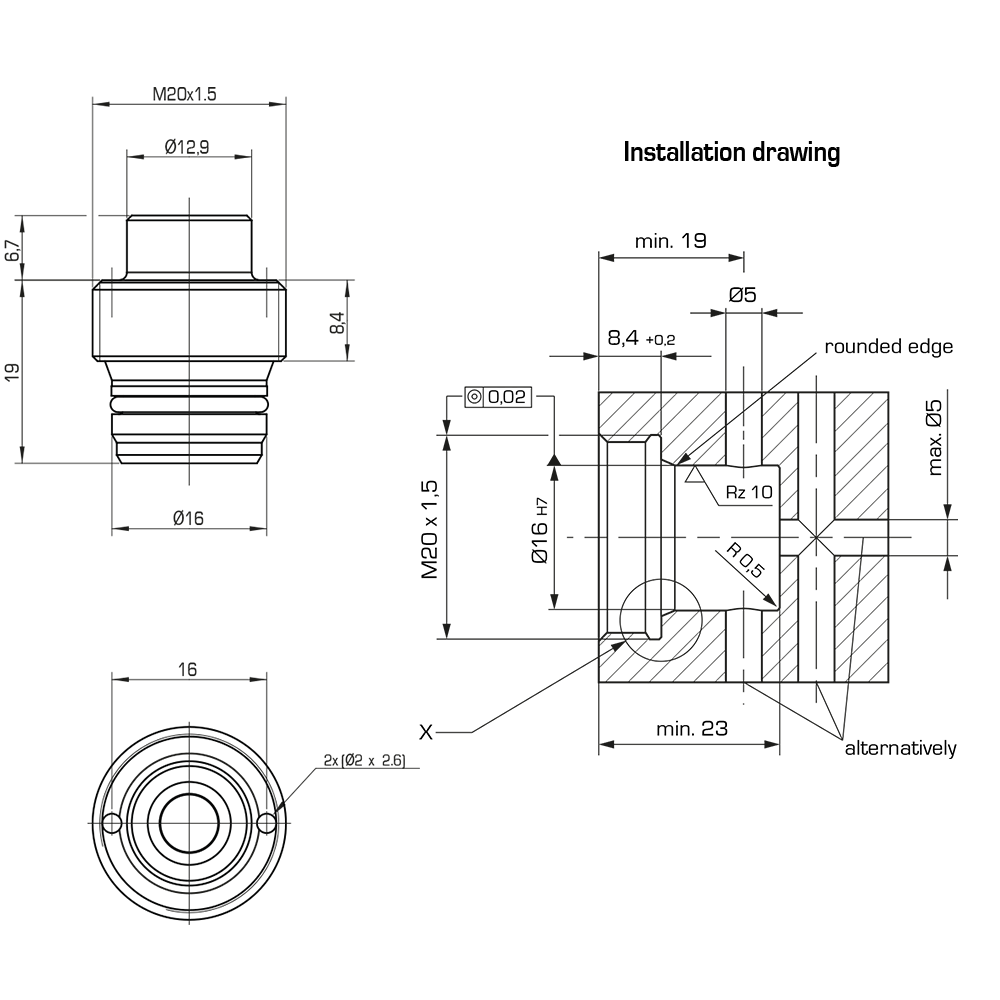

The sealing of the coupling mechanism is ensured at the bottom of the housing bore.

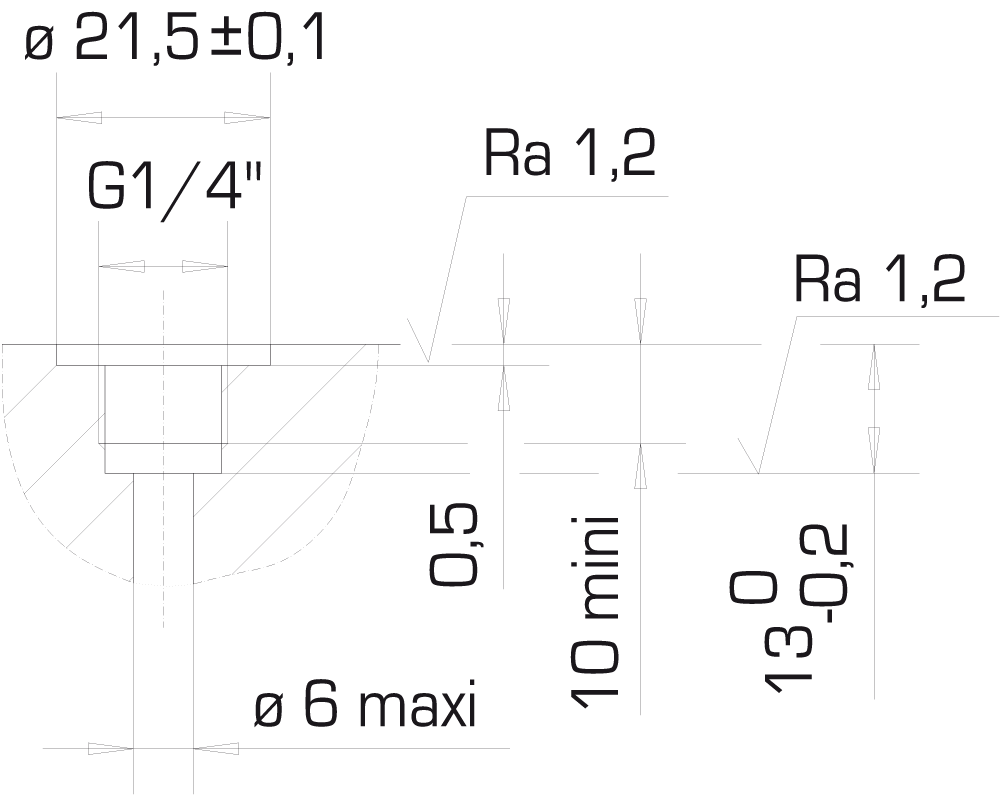

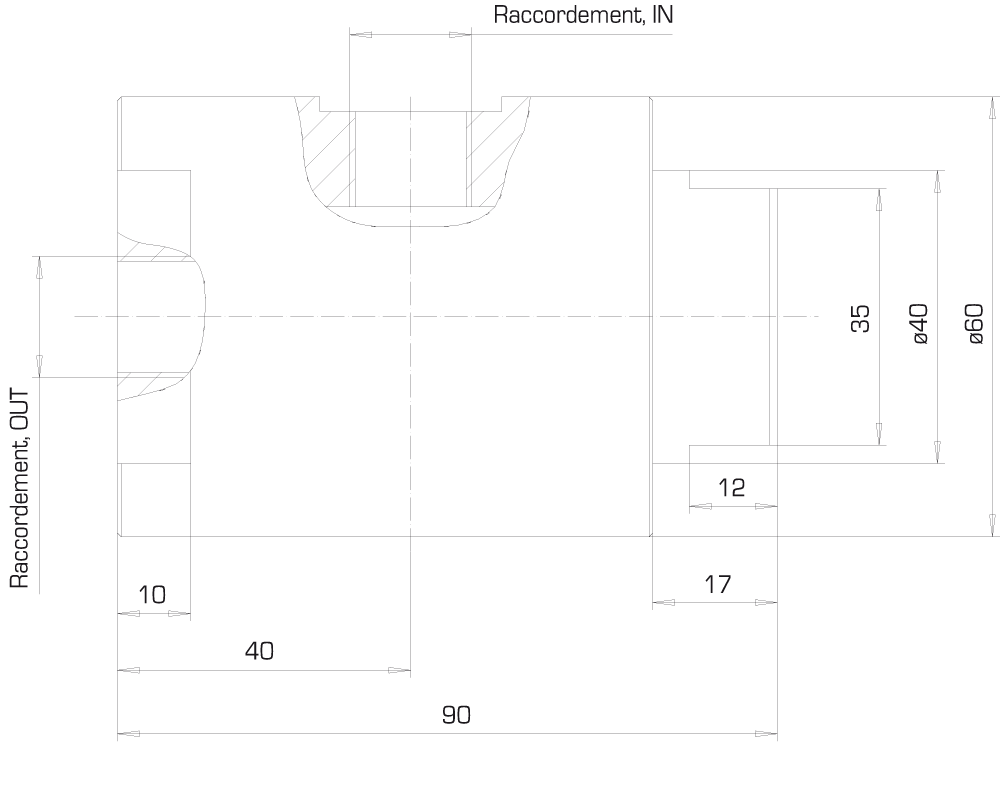

The required precision and surface condition of the housing must be respected.

Noticed

The axially acting front sealing surfaces must be protected from contamination. The fact that the front profiles of the coupling elements are smooth and flat reduces the risk of contamination and improves the possibility of cleaning the sealing surfaces by the customer before the coupling operation. Good results are obtained by washing and drying with compressed air.

- Positioning tolerance in axial direction for all coupling elements: +0,5 mm.

- Positioning tolerance in radial direction for the coupling end: +/- 0,3 mm.

- Allowable angular tolerance: +/- 1°.