Auto-Lock is a patented locking system based on the principle of the elastic expansion of metals under a fluid pressure.

Auto-Lock system

The female part of the Auto-Lock device has a bore inferior to the diameter of the rod on which it is mounted, creating a friction locking connection caused by the elastic deformation of the metals used. The unlocking is obtained by hydraulic pressure evenly applied between the two surfaces in contact.

Reverse Auto-Lock system

Reversely to the previous system, locking is obtained through application of hydraulic pressure and unlocking through lack of pressure.

Features and advantages of the Auto-Lock system

– The locking loads can reach 300 tons and hold the position with great precision during an unlimited length of time.

– The stroke is not limited and there exists an infinite variety of locking positions.

– The locking in insensitive to vibrations as well as to temperature variations.

– In case of accidental overloading, the rod will slide and the Auto-Lock will act as a brake. Provided the sliding is accidental and not repetitive, it will not bring about any damage.

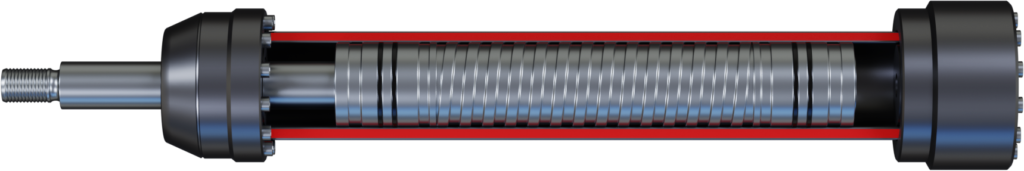

Autonomous Auto-Lock system

This system makes it possible to implement locking in any direction (translation-rotation, simultaneous translation and rotation) over long strokes. It is independent from the propelling system. Mounting should be carried out at the factory by means of a special tool which has to be adapted onto the end of the rod.

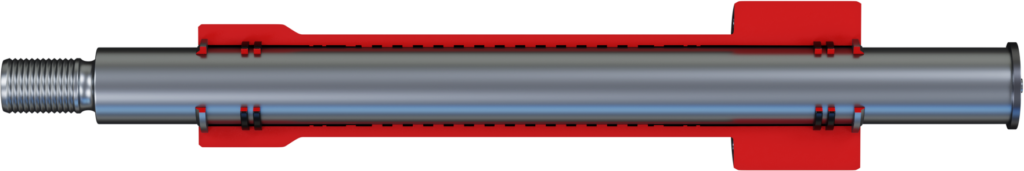

Linear cylinder with Auto-Lock on rod

This system combines the advantages of a hydraulic cylinder with those of an integrated locking system. The locking capacity of the Auto-Lock system is independent from the efforts carried out by the cylinder.

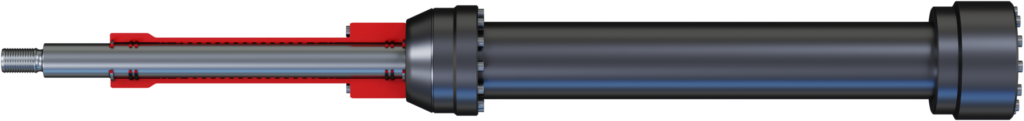

Auto-Lock on piston

Whilst this system has the same characteristics as the previous one, it is also particularly adapted to aggressive environments which need a special protection of the rod.