Swing clamps with planar rotation Guide

Definition of swing clamps

General

Swing clamps allow the working area to be cleared, thus facilitating workpiece loading and unloading operations. These clamps are designed for automated systems, and reduce non-productive time.

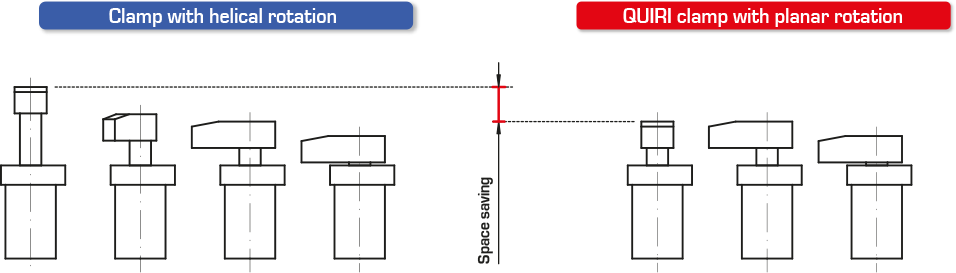

The exclusive planar rotation system reduces the space required for movement.

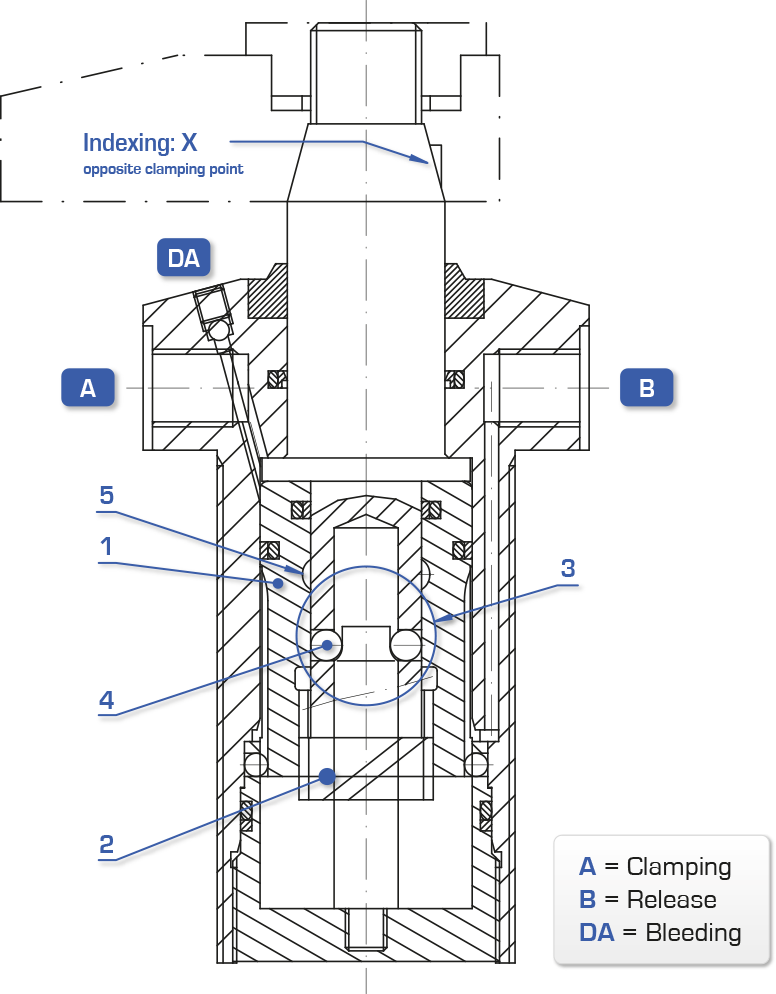

This clamp is designed to optimally distribute internal forces, thus increasing working life and reliability.

Construction

• all parts are made of treated high-strength steel.

• rod treated to prevent seizing and corrosion.

• the body is protected by anti-corrosion treatment.

• all our swing clamps have bleeders.

• no damage if rotation is impeded.

• no swing travel, so reduced wear and tear of rod seals

• easy removal of clamping arm

• all the clamps have indexable rods.

Special features of the system

The swing clamp rod rotates in a plane, thus allowing the clamping arm to move in a very restricted space. Such rotation is followed by displacement for clamping.

Both chambers of the double-acting clamp are always full of oil, making the system insensitive to external contamination.

Integrated safety function:

When the workpiece is clamped hydraulically using a swing clamp, hazardous movements must be avoided if pressure is lost or the force is incomplete. In that case, the workpieces must not fall even if they are installed at a height, in order to keep personnel and machinery safe.

Because of the unique design of the functions of the rotational movement and axial travel of Quiri swing clamps, which are hydraulically and mechanically separated, protection from such falls is fully integrated in planar swing clamps.

Safety in the case of loss of pressure:

If the seals fail, piping breaks, the hydraulic supply is lost, etc., the Quiri swing clamp only completes its axial clamping travel and is then held in place by an internal stop. Thus, the workpiece cannot fall out of the fixture, even when it is installed at a height, because it is held by the clamping arm. To return to the starting position, hydraulic pressure must be applied in the swing flange for it return to the initial position. That ensures that the workpiece can only move over the value of the defined axial displacement (clamping range).

The use of Quiri swing clamps offers maximum safety.

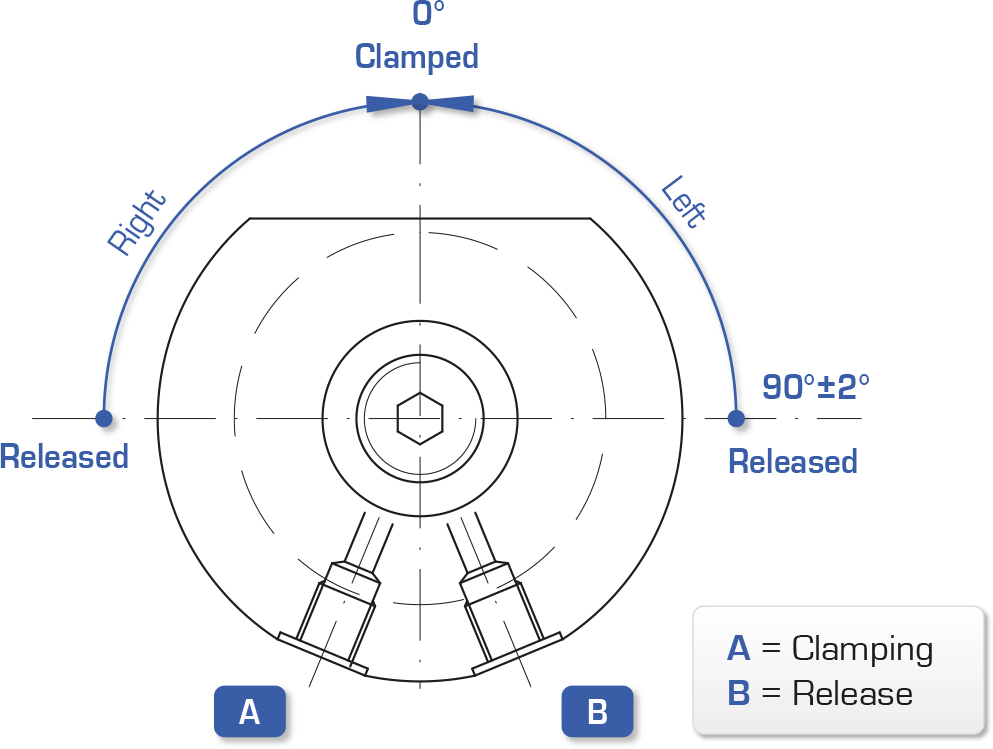

Direction and angle of rotation

The direction of rotation is indicated from the initial released position with the rod extended to the clamped position with the rod retracted, rod viewed from above.

Right = clockwise direction

Left = anticlockwise direction

Standard angle of rotation: 90° ± 2°.

All angle values between 0° and 90° available on request.

Clamp determination

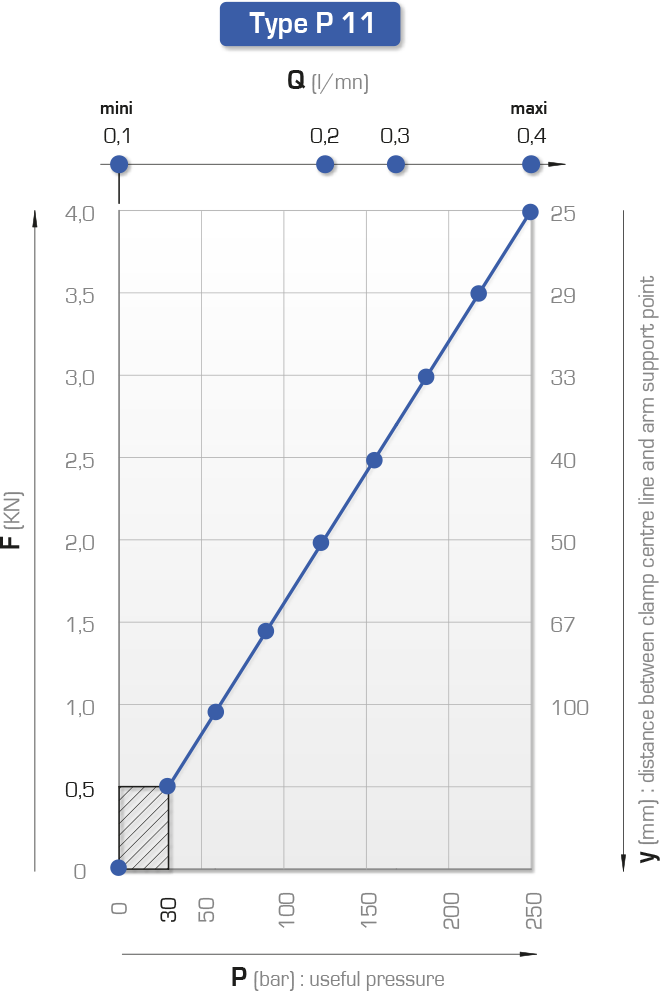

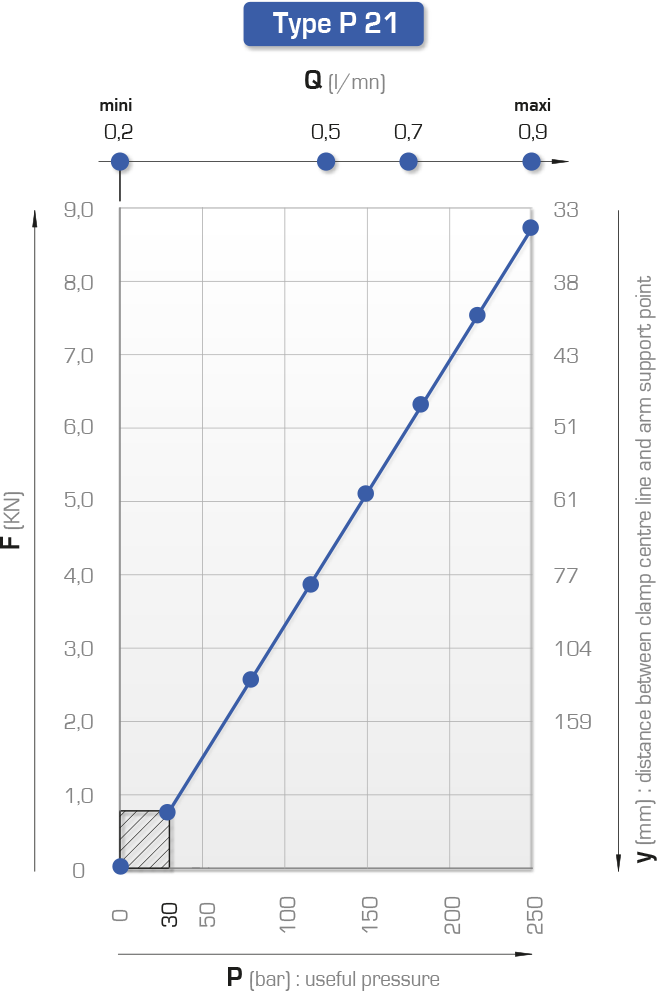

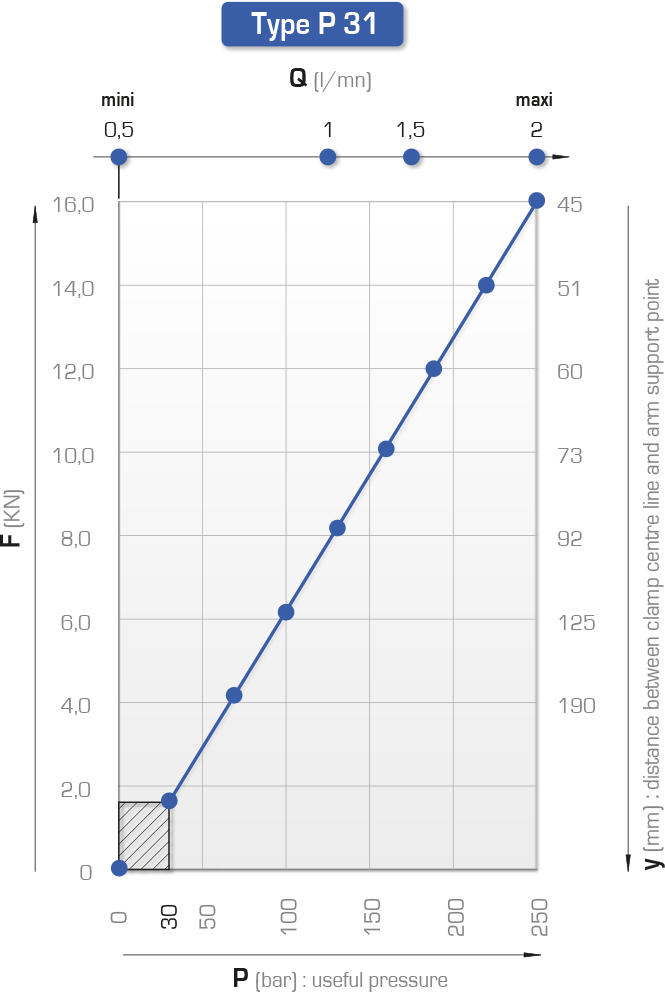

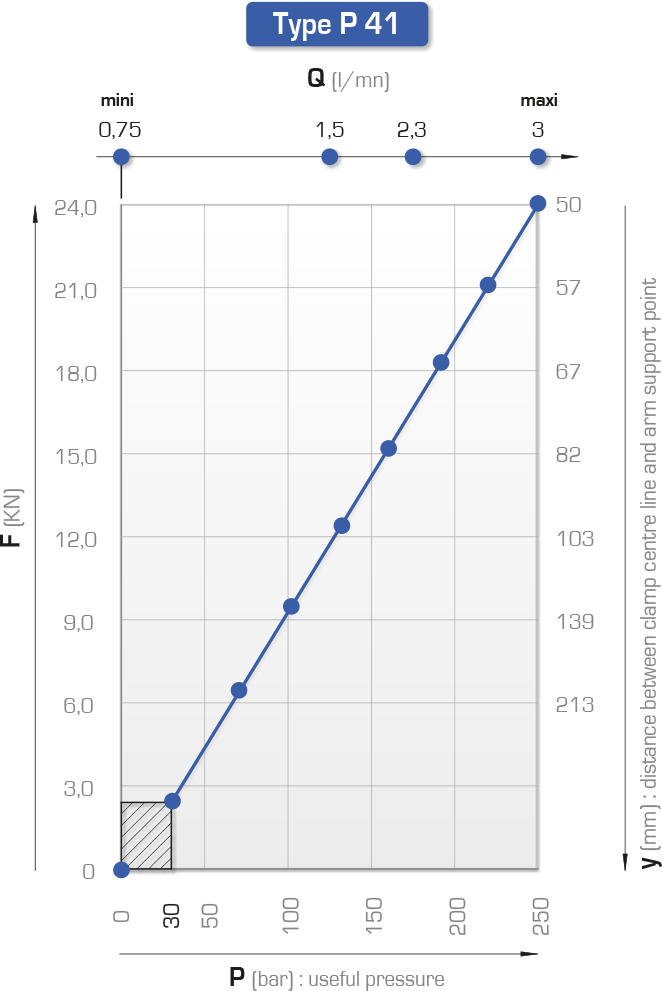

The maximum forces are provided for 250 bar pressure. This pressure is only permitted if the shortest of the three standard arms available is used.

Max force F (and thus max pressure) decreases proportionally with the length of the arm: see charts Type P21.

Max flow rate Q also decreases with the inertia of the arm; refer to the values indicated in the charts for standard arms. Please enquire if special arms are needed.

| Maximum pressure/standard clamping arm | |

| Maximum pressure | Type of arm |

| bar | |

| 250 | Short arm BC |

| 175 | Medium arm BM |

| 125 | Long arm BL |

Min operating pressure: 30 bar

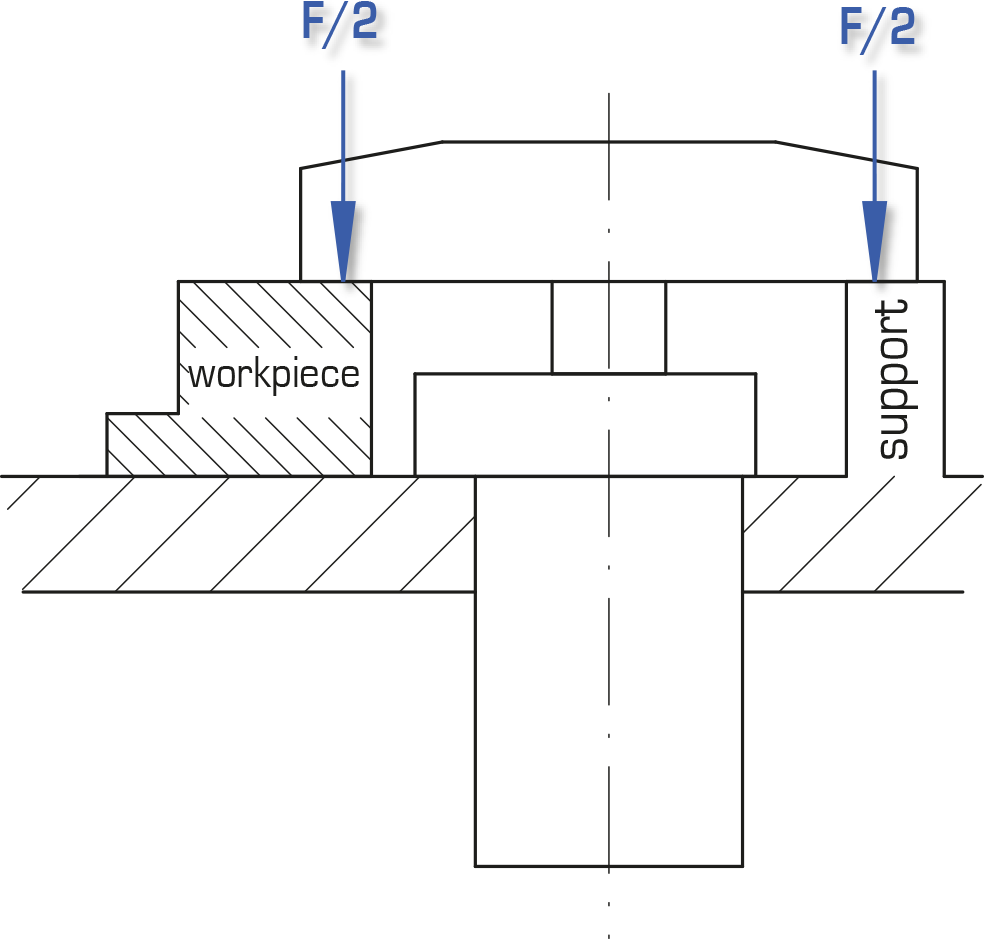

Using a symmetric double arm makes it possible to work with 250 bar, but the following formula must be applied:

Force (daN) /2 = Pressure (bar) x Cross section (cm2) ÷ 2

([A] in Important recommendations table)

Examples :

P11 : F/2 = P x 2,36 ÷ 2 P31 : F/2 = P x 9,45 ÷ 2

P21 : F/2 = P x 4,71 ÷ 2 P41 : F/2 = P x 14,12 ÷ 2

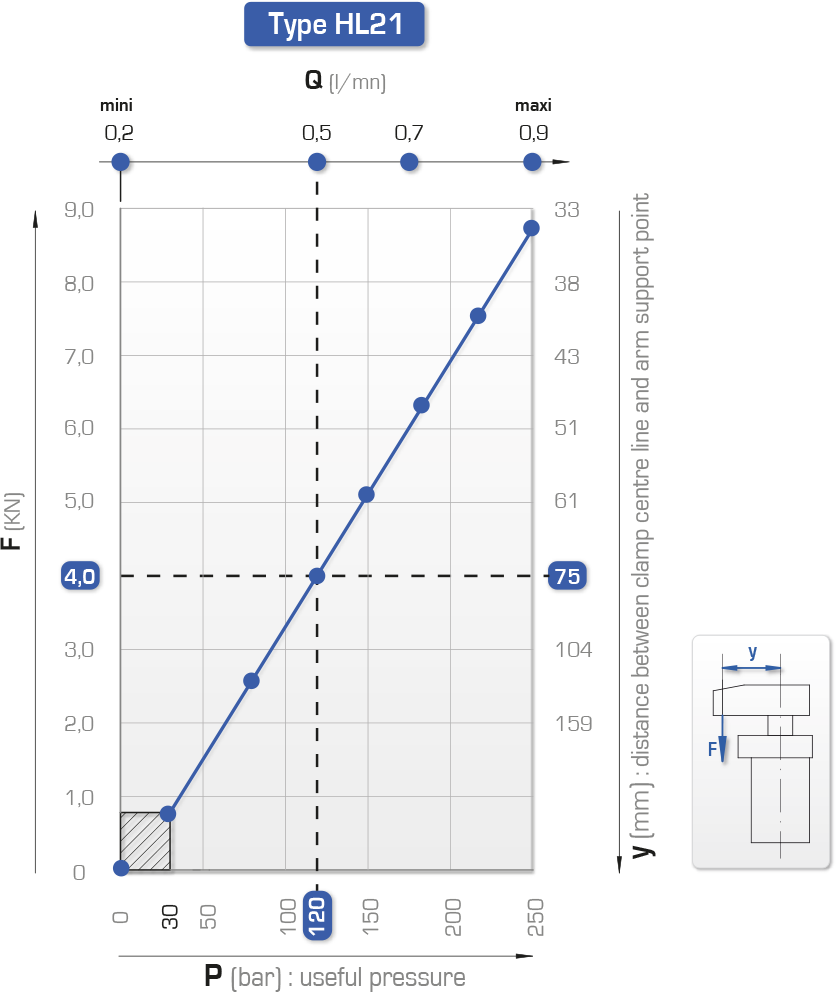

Example of use of diagrams

The diagram opposite allows you to determine the maximum force developed by the clamp and the maximum pressure depending on the type of arm used: BC, BM, or BL. They also indicate the limit values of flow rate Q.

The maximum force developed by a clamp of the P21 type with a BL 21 arm that is 75 mm long is 4 kN at 120 bar with a maximum flow rate Q of 0.5l/min per clamp.

To determine special arm specifications, use the charts at the bottom of the page.

Operating pressure

• minimum : 30 bar

• maximum : 250 bar with short arms (see chart)

Maximum temperatures

• 70°C

• please enquire for temperatures above 70°C

Important recommendations

A – This value provides a rough idea of the clamp to select. Always refer to the diagram of forces present on the clamp drawings to define the maximum pressure and force depending on the arm length “y”.

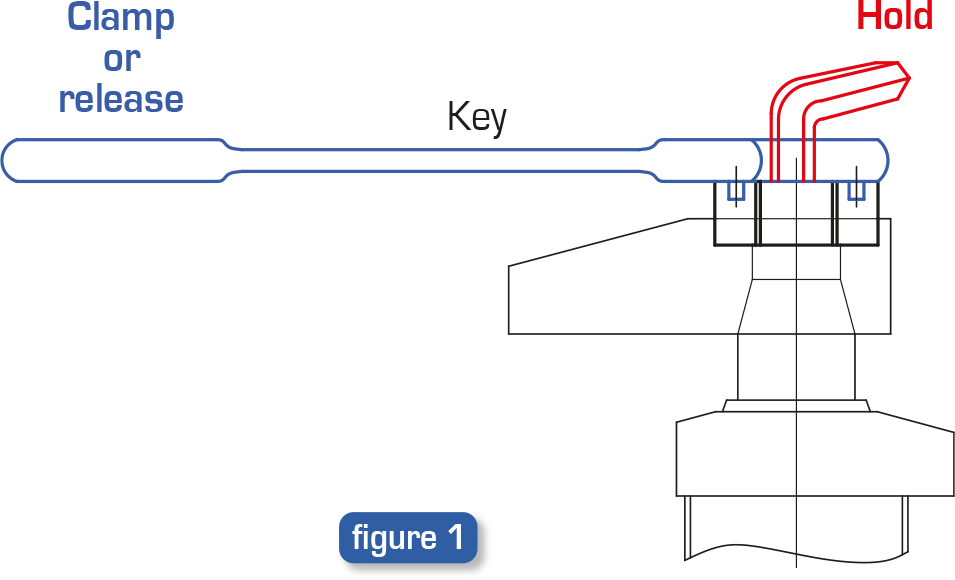

B – The rod has a tapered end and is threaded for fastening the clamping arm with braking. When locking the nut, the rod must absolutely be prevented from rotating in order not to transmit the tightening torque to the internal mechanism.

There are two ways of doing this:

• hold the rod with a hexagon spanner (see Figure 1)

• hold the arm (mounted on the clamp) in a vice during clamping

C – The indicated value is the maximum travel of the clamp. For clamping a workpiece, the useful travel is between the minimum and maximum values indicated in the table of characteristics below.

D – The maximum recommended flow rate will vary with the type of clamp and the inertia of the clamping arm. Refer to the table and if possible, provide a nozzle or adjustable restrictor in the distribution circuit. The flow rate must be multiplied by the number of clamps operating at the same time: ensure that minimum flow rates are observed.

E – This is the volume of oil displaced during over the total travel range.

F – Direction of rotation of the rod from the released position to the clamped position. Rod seen from above

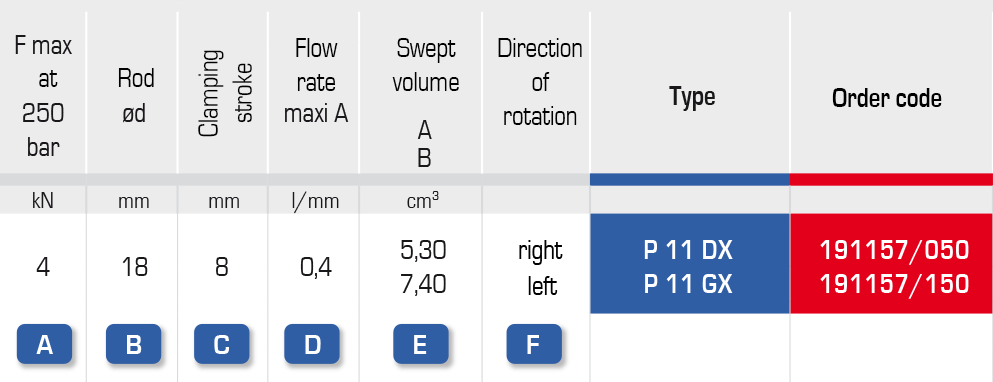

Characteristics

See table opposite.

CAUTION

The table opposite is provided for guidance..

To determine the actual forces, please use the charts provided at the bottom of the page, which take account of efficiency.

For flow rate limitation, see the bottom of the page.

| A = clamping

B = release |

Unit | P11 | P21 | P31 | P41 | |

| Section | A | cm2 | 2,36 | 4,71 | 9,45 | 14,42 |

| B | 4,91 | 9,62 | 19,63 | 28,27 | ||

| Swept volume | A | cm3 | 5,3 | 15 | 41 | 74 |

| B | 7,4 | 21 | 53 | 88 | ||

| Flow rate | max | l / mn | 0,4 | 0,9 | 2 | 3 |

| Cycle time | A | s | 0,75 | 1 | 1,2 | 1,5 |

| B | 1,1 | 1,4 | 1,6 | 1,8 | ||

| Travel | max | mm | 6 | 10 | 10 | 10 |

| min | 2 | 3 | 3 | 3 | ||

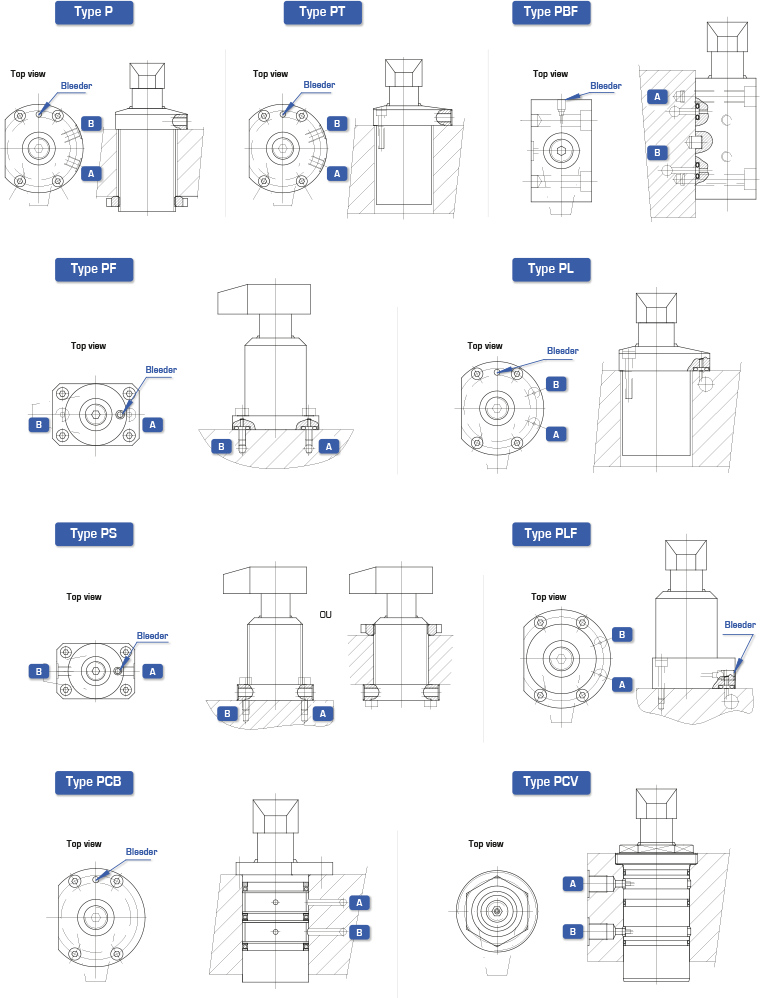

Fixture examples