These clamping elements allow positioning with repeatability to the hundredth before locking.

Their operation is hydraulic, two hydraulics supplies and a vent are required.

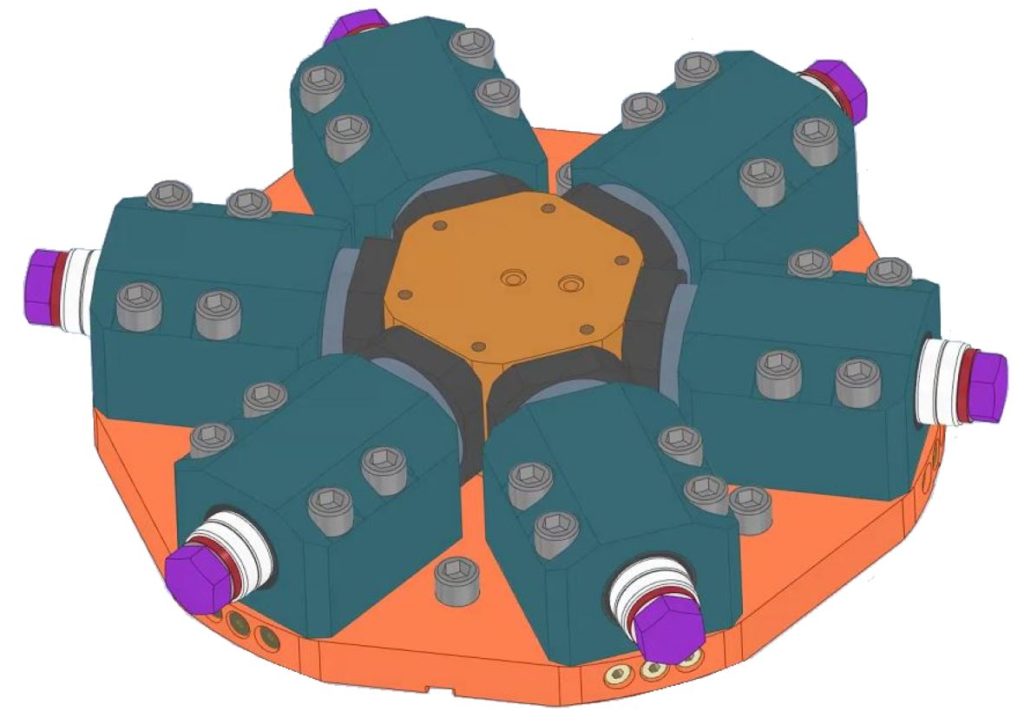

These sets are customizable as follows :

- the shape and diameter of the part (Ø200m to 3000mm)

- the weight of the part (5kg to 800kg)

- the number of centering and tightening points required

The centering of the parts is ensured by the compensation of the forces applied to the part by precision springs housed in the cylinders.

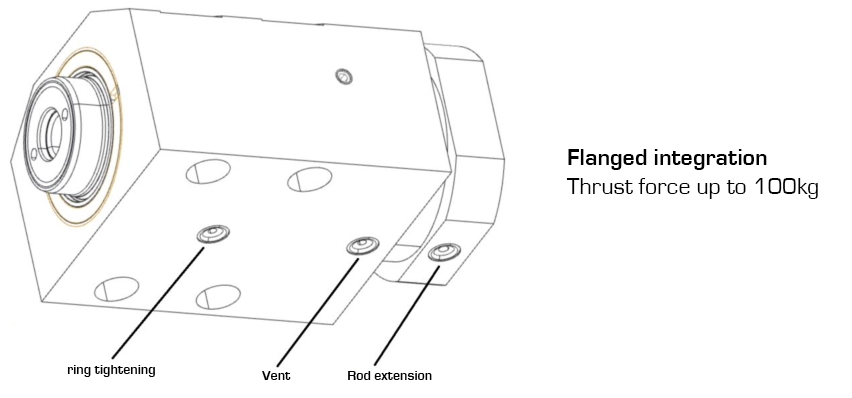

These cylinders of different sizes and configurations are available individually for specific integrations into the tools.

Their use is polyvalent :

- Retacking / positioning of a part before blocking.

- Prestressing of a part before blocking

- Clamping of a part on its internal diameter then locking of the system

- Deformation of a part before blocking

- Centering a part before locking

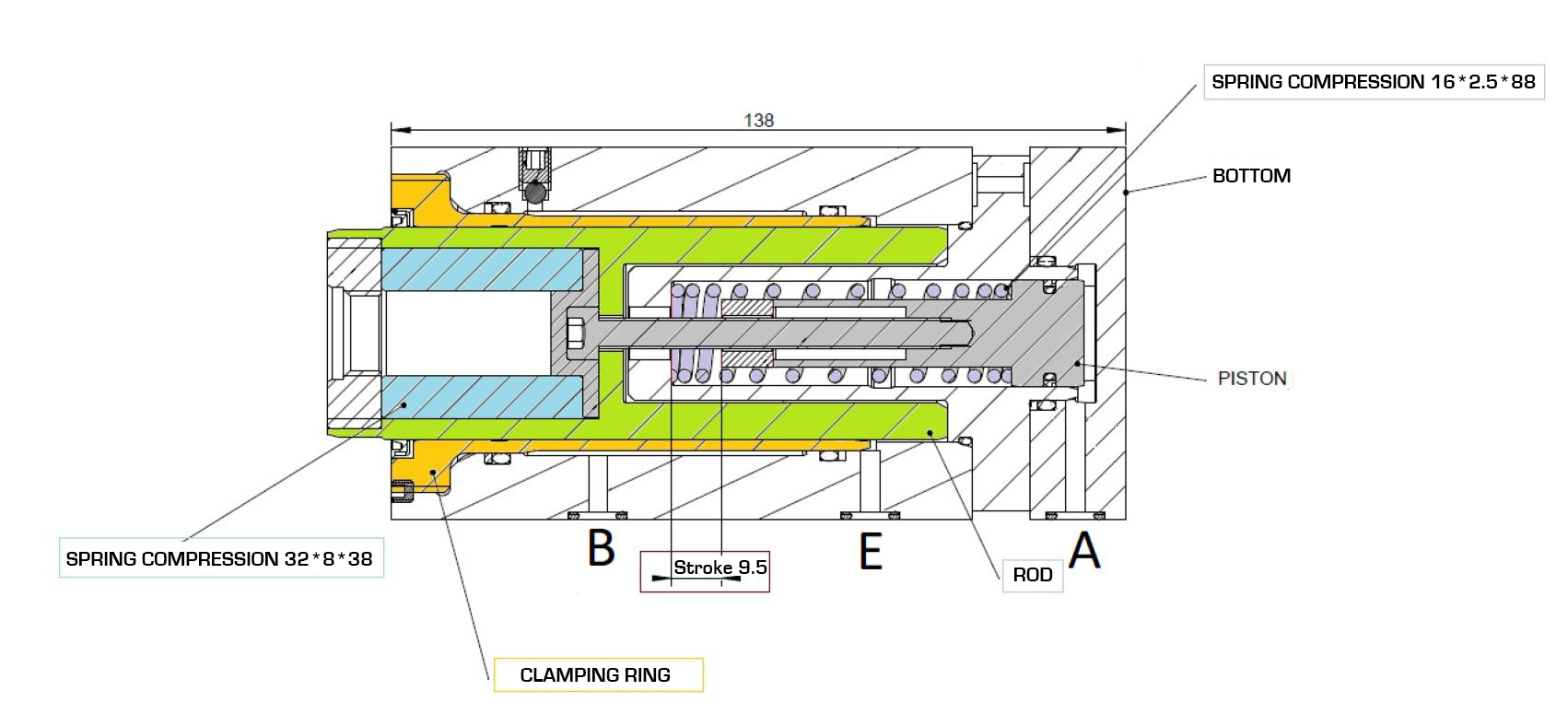

Principe of operation :

- A rod outlet port A

- A blocking hole B

- A vent port E

The piston performs its entire stroke once supplied by hydraulic pressure.

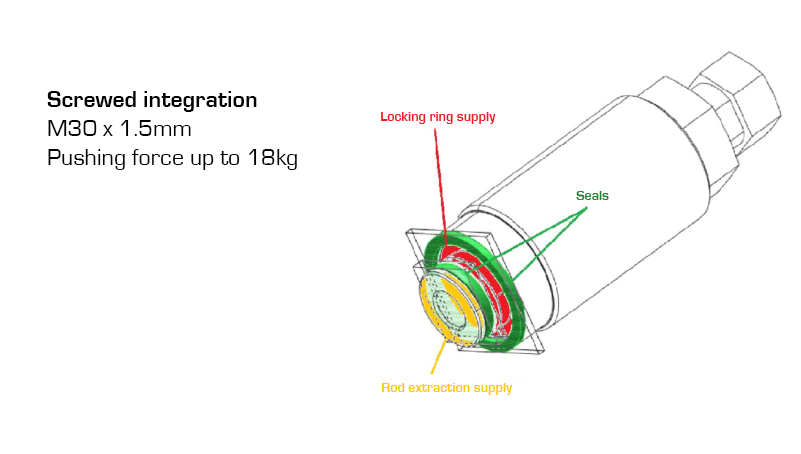

The green rod makes contact and adjusts according to the position of the part.

The blue push spring ensures and regulates the contact force with the workpiece.

The yellow bronze ring holds the green rod in position (rod lock).

A purple return spring allows the cylinder rod to retract when hydraulic pressure is released.

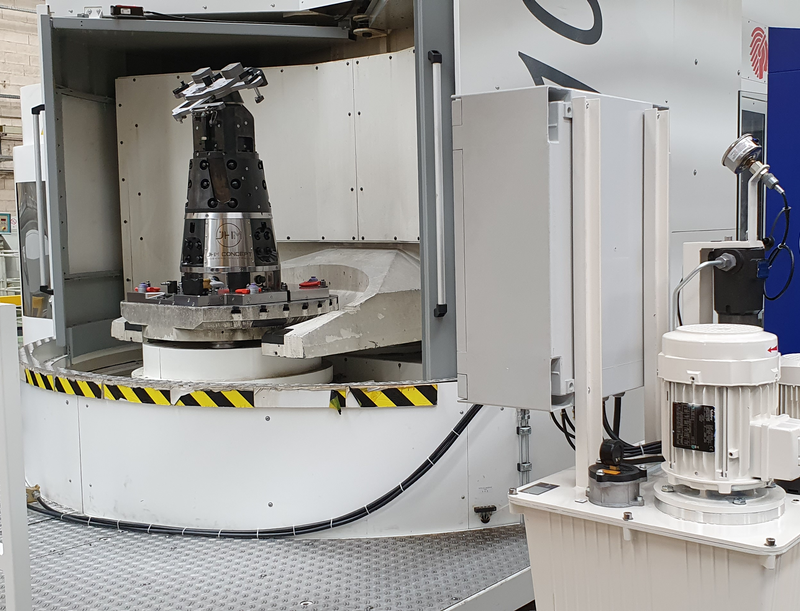

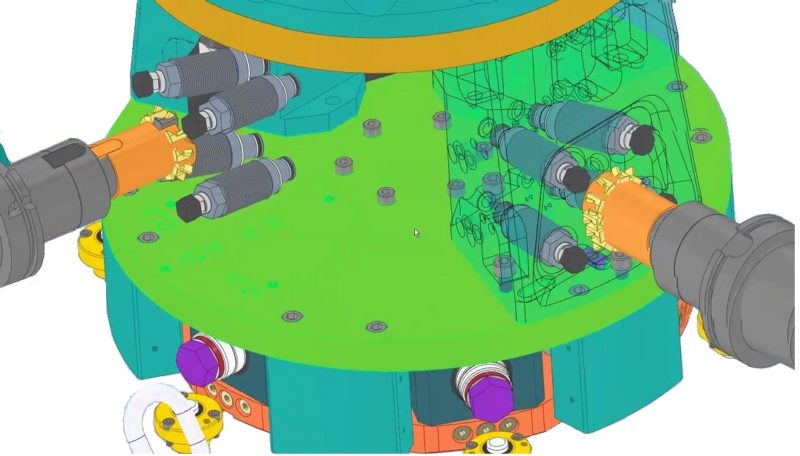

Example of application :

Tooling equipped with a hydraulic self-centering clamping and positioning element at its base as well as several QUIRI blocker applicator cylinders. Two QUIRI hydraulic zero points placed at the top of the tooling secure the part once it is centered and under prestressing.