INFLATING & PRESSURISING GAS SPRINGS

Inflating process of gas springs connected for equal pressure

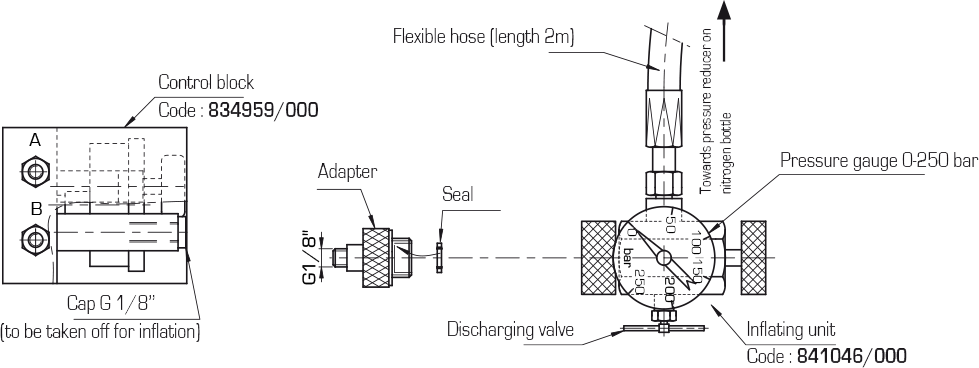

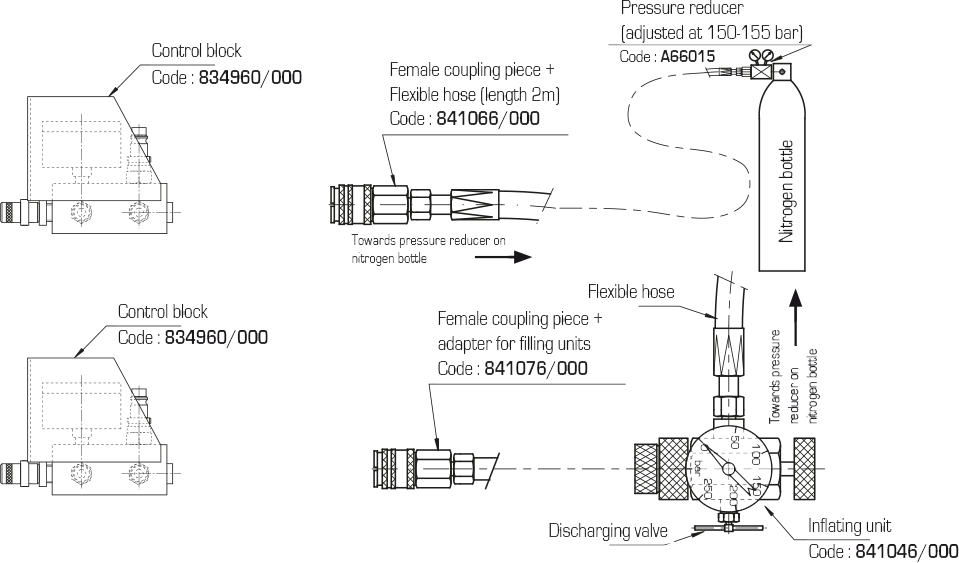

• Confirm that the pressure reducer has been connected to the nitrogen bottle and adjust the output pressure to 150 to 155 bar (15 to 1.5 MPa).

• Connect the adapters to the inflating unit.

• Connect the inflating unit to the control panel.

• Close the pressure reducer.

• Open the nitrogen bottle.

• When the inflating gauge indicates the pressure that you need, please wait for a while (about 10 seconds), the piping system pressure will stabilize.

• Close the nitrogen bottle.

• Open discharging valve to release the pressure.

• Remove the inflating unit from the control panel.

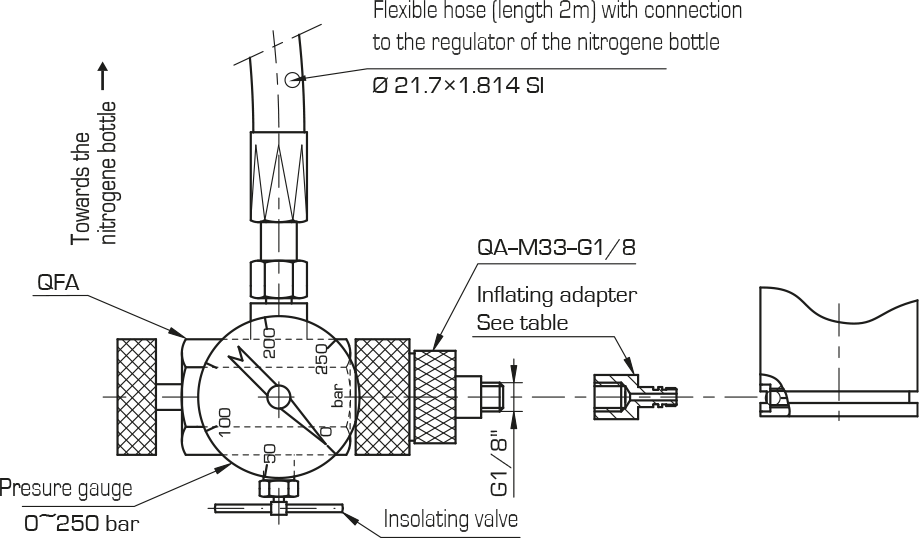

Control block with G1/8″ adapter

To inflate the piping system with standard G1/8″ adapter, you can use standard inflating units and G1/8″ adapter.

Control block with CEJN adapter

You can use self-lock fast coupling adapter to connect it.

Notice : The fast coupling should be ordered with inflating units separately. The pressure reducer should be ordered separately.

Ajust the pressure of gas springs

The inflating device is designed to pressurize and depressurize gas springs

Use of the device as a pressure tester is not recommended, as each test result leads to a loss of pressure of approximately 10 %.

The pin ø4 mm is designed to depressurize a gas spring, but is not required for pressurizing.

Each pressurising kit (Code 841046/000) includes :

• 1 pressurizing assembly (Code : A63295) with gauge 0-250 bar + flexible hose (2m) + valve spanner.

• 1 adapter MM M33x1,5 – G1/8’’ + 1 pin ø4 to direct inflating in G1/8’’ threads (Code : 831050/000)

• 1 adapter MF 1/16NPS – G1/8’’ (Code : 831052/000)

• 1 adapter MF M6 – G1/8’’ type A (Code : 831101/000)

• 1 adapter MF M6 – G1/8’’ type B (Code : 831113/000)

MOUNTING A – Inflating directly with the adapter

MOUNTING B – Inflating with adapter and tip

| Type of Gas spring | Mounting | Tip to use |

| RG 19 | B | 831113/000 |

| MRG | B | 831113/000 |

| RMG/T/E | B | 831052/000 |

| RG 32 | B | 831113/000 |

| RG 300 F | B | 831052/000 |

| RGP 170 à RGP 2400 | B | 831113/000 |

| RGP 4200 à RGP 9500 | A | Direct sur adaptateur |

| RGT 1000 à RGT 9500 | A | Direct sur adaptateur |

| RGC 420 et RGC 750 | B | 831113/000 |

| RGC 1000 à RGC 3000 | B | 831101/000 |

| RGC 4700 à RGC 18300 | A | Direct sur adaptateur |

| RGH | B | 831113/000 |

| RG 250 | A | Direct sur adaptateur |

| RG 500 C10 à C100 | A | Direct sur adaptateur |

| RG 500 C125 à C160 | B | 831101/000 |

| RG 750 C13 à C160 | A | Direct sur adaptateur |

| RG 750 C200 à C300 | B | 831101/000 |

| RG 1500 à RG 10000 | A | Direct sur adaptateur |

Procedure

• Depressurize the gas spring completely by depressing the valve with the special QUIRI tool, whilst keeping the piston rod of the gas spring fully extended.

• Refill the gas spring to the required pressure level (eg. 100 bar).

• Check the valve tightness with a drop of oil inside the pressuring orifice.

• If the valve is not tight, replace it with new one.

• Do not forget to indicate the new inflating pressure on the gas spring body and identify if with a blue adhesive strip if the new pressure is lower than 150 bar.

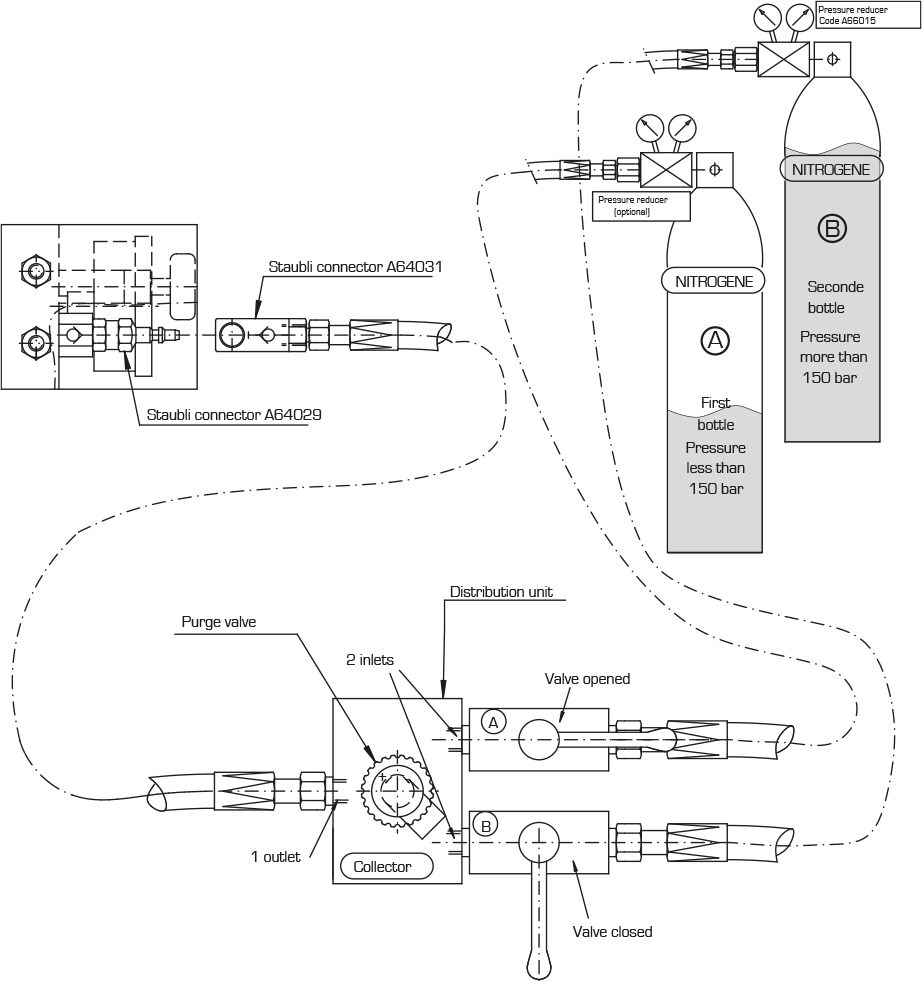

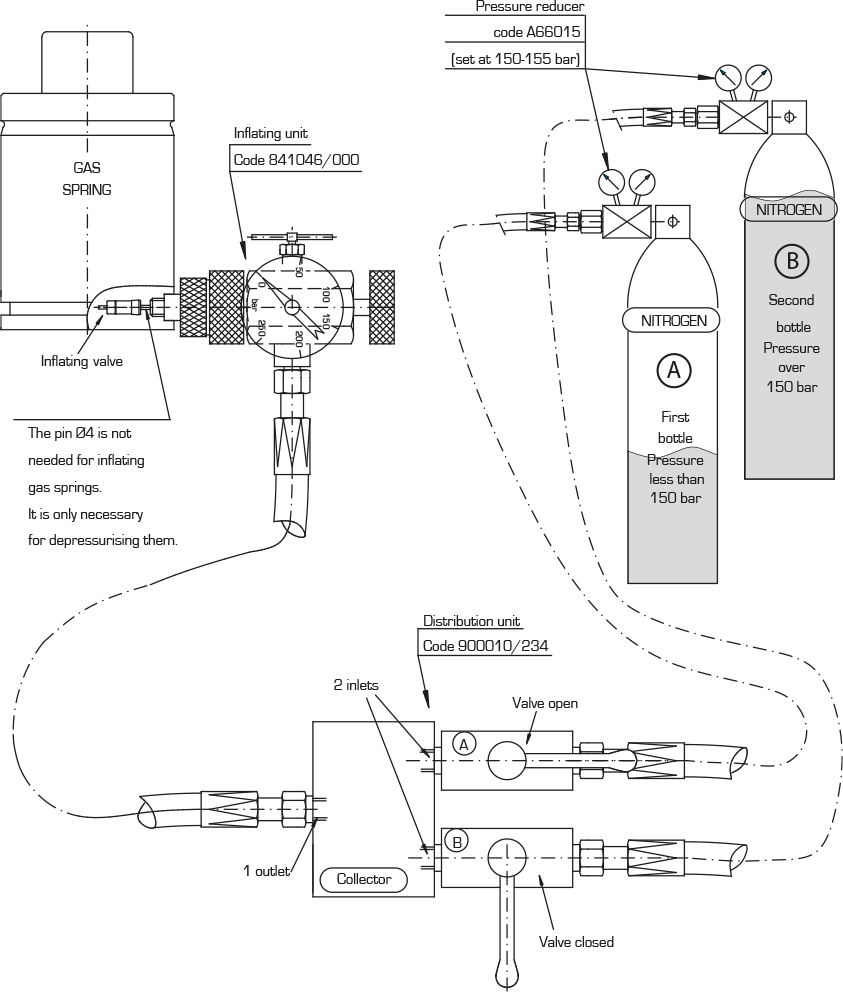

INFLATING GAS SPRINGS WITH 2 NITROGEN BOTTLES

Example : bottle A contains 13.5 MPa, use bottle B to add 1.5 MPa. You can use bottle A until bottle B is lower than 15Mpa.

Inflating advice :

INFLATION OF CONTROL PANEL EQUIPED WITH STAUBLI CONNECTOR WITH 2 NITROGEN BOTTLES

THE ADVANTAGE OF THAT EQUIPMENT IS THE OPTIMAL USE OF NITROGEN BOTTLE CONTENTS

Inflating advice :

• First of all, setup the inflating pressure on the pressure reducer.

• Connect the STAUBLI connector to the control panel.

• Open valve A and close valve B, then fill the gas spring with maximum pressure from the first bottle.

• Close valve A and open valve B, then fill the gas spring with about 155 bar.

• Close valve B and the valves on the nitrogen bottle.

• Open discharging valve on the collector to remove pressure.

• Disconnect the STAUBLI connector by pushing the knob.

• WARNING! : NEVER REMOVE THE CONNECTOR WHILE UNDER PRESSURE.