Linear cylinders

Other products

Access Linear cylinders 's products

Access selection

Back to Hydraulic Clamping Systems

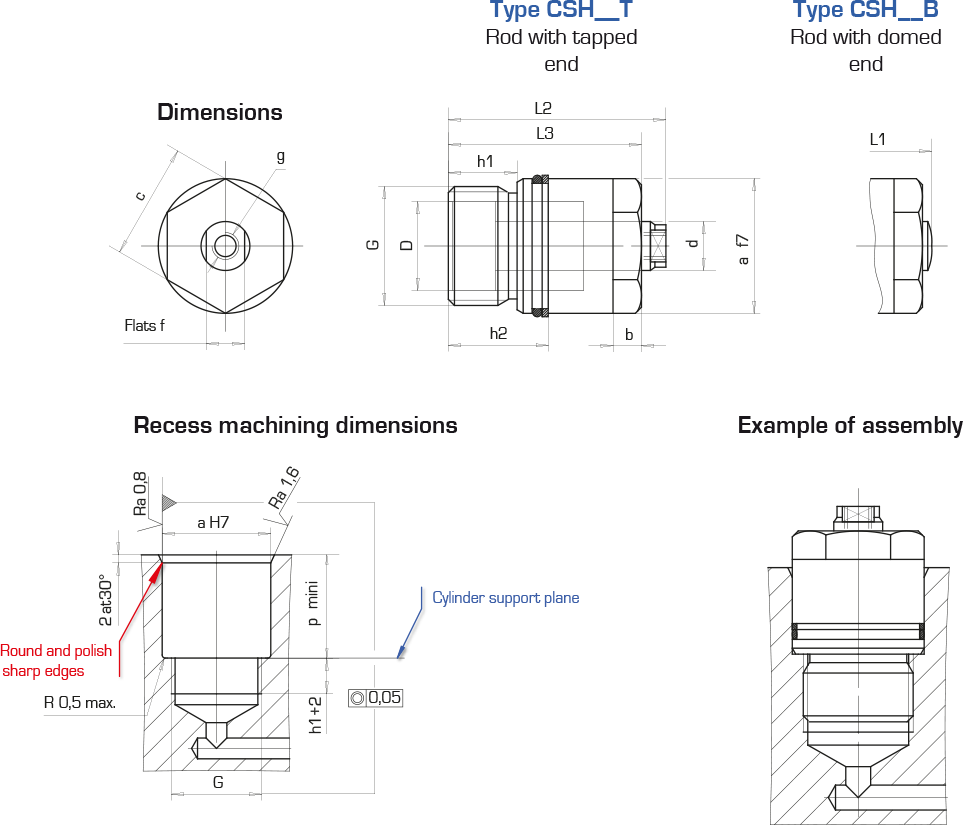

Single-acting cartridge clamp – hexagon head CSH

Single-acting - spring return- hexagon head

Max force at 350 bar: 2.7 to 109 kN

• screw type cartridge

• direct supply in the block

• spring return

• domed or tapped end with flats

• supplied with O-ring and anti-extrusion ring

• steel body with anti-corrosion treatment

• treated steel rod

Part numbers of packs of nitrile seals for CSH: 11* ***/900

Part numbers of packs of Viton™ seals for CSH. V: 11* ***/960

| Force

at 350 bar |

Travel | Thrust cross section | Rod

øD |

Rod

ød |

Type | Reference | |||||||||||||

| L1

|

L2

|

L3

|

h1

|

h2

|

øa

|

b

|

c

|

f

|

G

|

g

|

p

min |

||||||||

| kN | mm | cm2 | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | |||||

| 2.7 | 10 | 0.78 | 10 | 5 | CSH 5 B | 111 100/200 | 37 | 40 | 35 | 12 | 17 | 16 | 2 | 13 | – | M15 x 1.5 | M3 lg. 6 | 9 | 3D |

| CSH 5 T | 111 100/300 | ||||||||||||||||||

| 7 | 12 | 2.0 | 16 | 8 | CSH 10 B | 111 101/200 | 47 | 50 | 44 | 13 | 20 | 24 | 3 | 19 | – | M22 x 1.5 | M5 lg. 10 | 11 | 3D |

| CSH 10 T | 111 101/300 | ||||||||||||||||||

| 11 | 12 | 3.14 | 20 | 10 | CSH 15 B | 111 102/200 | 51 | 54 | 47 | 16 | 21 | 28 | 4 | 24 | 8 | M26 x 1.5 | M6 lg.12 | 11 | 3D |

| CSH 15 T | 111 102/300 | ||||||||||||||||||

| 17.1 | 16 | 4.9 | 25 | 14 | CSH 25 B | 111 103/200 | 59 | 62 | 55 | 15 | 25 | 34 | 4 | 30 | 11 | M32 x 1.5 | M8 lg. 12 | 13 | 3D |

| CSH 25 T | 111 103/300 | ||||||||||||||||||

| 28 | 16 | 8.0 | 32 | 16 | CSH 40 B | 111 104/200 | 64 | 67 | 59 | 17 | 25 | 42 | 5 | 36 | 13 | M40 x 1.5 | M10 lg. 15 | 12 | 3D |

| CSH 40 T | 111 104/300 | ||||||||||||||||||

| 44 | 20 | 12.56 | 40 | 20 | CSH 65 B | 111 105/200 | 86 | 89 | 80.5 | 22 | 34 | 52 | 6 | 42 | 17 | M50 x 1.5 | M12 lg. 20 | 16 | 3D |

| CSH 65 T | 111 105/300 | ||||||||||||||||||

| 68.7 | 20 | 19.62 | 50 | 25 | CSH 100 B | 112 090/200 | 89 | 92 | 81 | 28 | 37 | 64 | 8 | 56 | 19 | M62 x 1.5 | M16 lg. 22 | 13 | 3D |

| CSH 100 T | 112 090/300 | ||||||||||||||||||

| 109 | 25 | 31.15 | 63 | 32 | CSH 160 B | 112 091/200 | 104 | 108 | 95 | 30 | 41 | 80 | 10 | 64 | 24 | M78 x 1.5 | M20 lg. 30 | 15 | 3D |

| CSH 160 T | 112 091/300 | ||||||||||||||||||