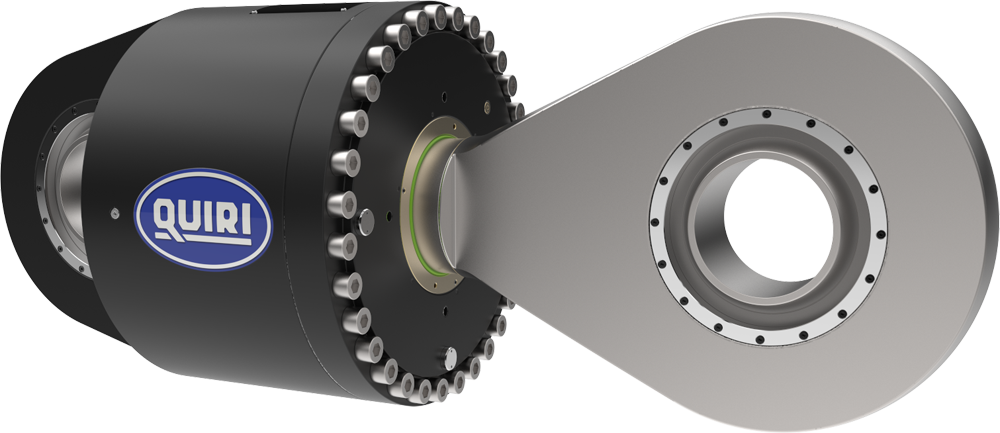

Large bore snubbers

DALB

Introduction

Large Bore Snubbers (DALB) are used for high load charge, more than 600 kN.

Used for conventional or nuclear applications.

Qualified for nuclear applications, used for steam generator and large pumps, in primary loop of nuclear power plants.

Special fabrication on demand.

Raw materials

Forged stainless steel rod with chemical nickel coating or chrominium.

Forged steel for body and internal parts.

Dynamic characteristics at ambient temperature, 15°C to 35°C

Hereofter standard values, (others available on demand)

FN is the Nominal load of the snubber

• Drag force at slow speed, before locking : < 40 kN (DA12)

• Lockup velocity : 6 mm/min < LV < 60 mm/min

• Drift speed after locking : < 10 mm/min under maximum load

• Lost motion : < 1 mm

• Theoretic stiffness in tension : > 1200 kN/mm under maximum load (DA12)

• Theoretic stiffness in compression : > 1500 kN/mm under maximum load (DA12)

• Functional temperature : 10°C to 60°C

Environment conditions

For nuclear or conventionnal applications

Temperature:

Normal operating conditions : 0°C to +80°C

Minimum storage temperature : – 40°C

Humidity: 100 %

External pressure:

Service pressure : 1 bar

Accidental pressure : 5 bar

Permissible load in kN

The permissible load in terms of dynamic stress in the table below has been calculated in accordance with RCCM code vol. H level S1.

Load definition :

Normal/Disturbed – Level A/B: Here are estimated all loads due to normal functioning, including normal transitional regime during operation of the plant. And also some disturbed loads due to normal functioning of the plant.

Emergency : Level C: Here are estimated all loads outside to normal operation due to particulars situations, possibly safety shutdown earthquake.

Faulted : Level D: Here are estimated all loads due to accidental situations. The snubbers should undergo verification after such an event.

| Model | Total stroke | FN load level A/B/80°C |

Emergency load level C/80°C |

Faulted load level D/150°C |

| (mm) | (kN) | (kN) | (kN) | |

| DA8 | 150, 300 | 1100 | 1463 | 2000 |

| DA9 | 120 | – | – | 3500 |

| DA10 | 100 | – | – | 4500 |

| DA11 | 100 | – | – | 6500 |

| DA12 | 100 | – | – | 8500 |

Life under dynamic stress

The snubbers may be subject to the total dynamic loads below, without any adverse effect on operating, at temperature less than 80°C.

| Load (in % FN) | Number of cycles |

| 10% | 5 x 106 |

| 50% | 106 |

| 100% (level A/B) | 105 |

| 133% (level C) | 103 |

| (level D) | 102 |

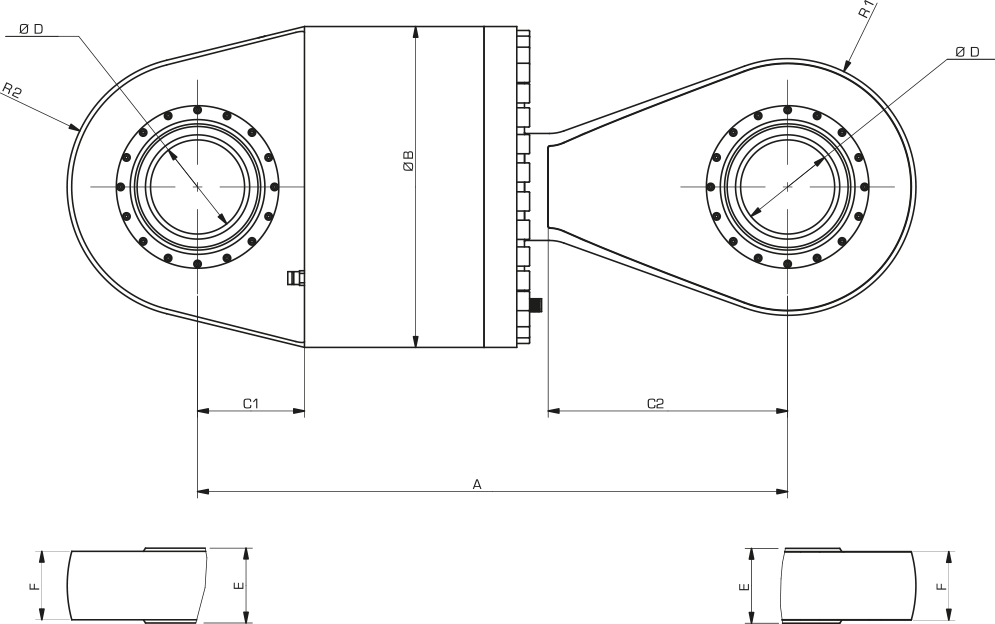

Dimensions

| Type | Nominal Load Level B |

Faulted Load Level D |

Stroke

|

A half stroke |

Ø B

|

C1

|

C2

|

Ø D

|

E

|

F

|

R1

|

R2

|

Weight without bracket |

| (kN) | (kN) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (kg) | |

| DA8-150 | 1100 | 2000 | 150 | 1100 | 330 | 180 | 125 | 90 | 85 | 80 | 125 | 140 | 500 |

| DA8-300 | 1100 | 2000 | 300 | 1603 | 330 | 180 | 125 | 90 | 85 | 80 | 125 | 140 | 600 |

| DA9-120 | – | 3500 | 120 | 1200 | 620 | 170 | 170 | 140 | 90 | 80 | 240 | 225 | 1200 |

| DA10-100 | – | 4500 | 100 | 1080 | 520 | 190 | 180 | 140 | 90 | 80 | 200 | 205 | 1000 |

| DA11-100 | – | 6500 | 100 | 1320 | 670 | 210 | 550 | 220 | 175 | 160 | 340 | 260 | 2000 |

| DA12-100 | – | 8500 | 100 | 1380 | 750 | 230 | 550 | 220 | 175 | 160 | 340 | 305 | 2400 |

Other load, stroke or characteristics on demand.