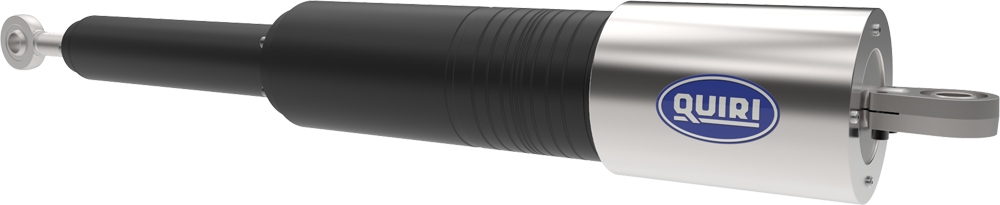

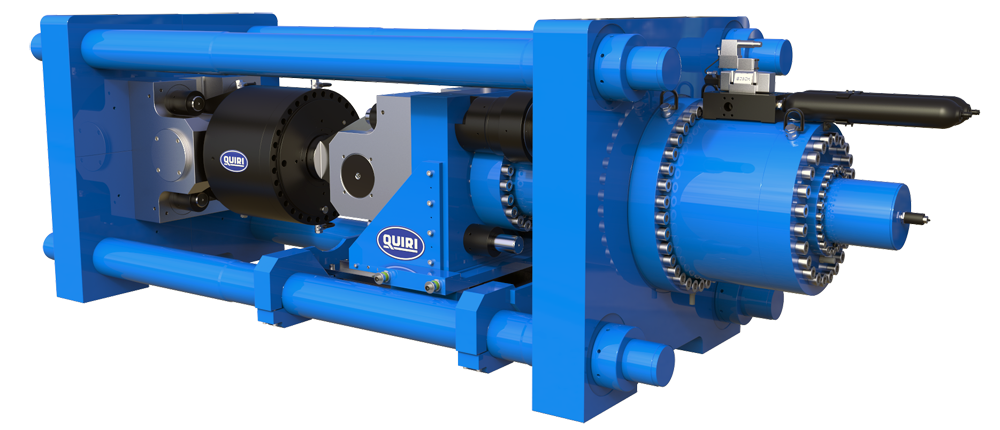

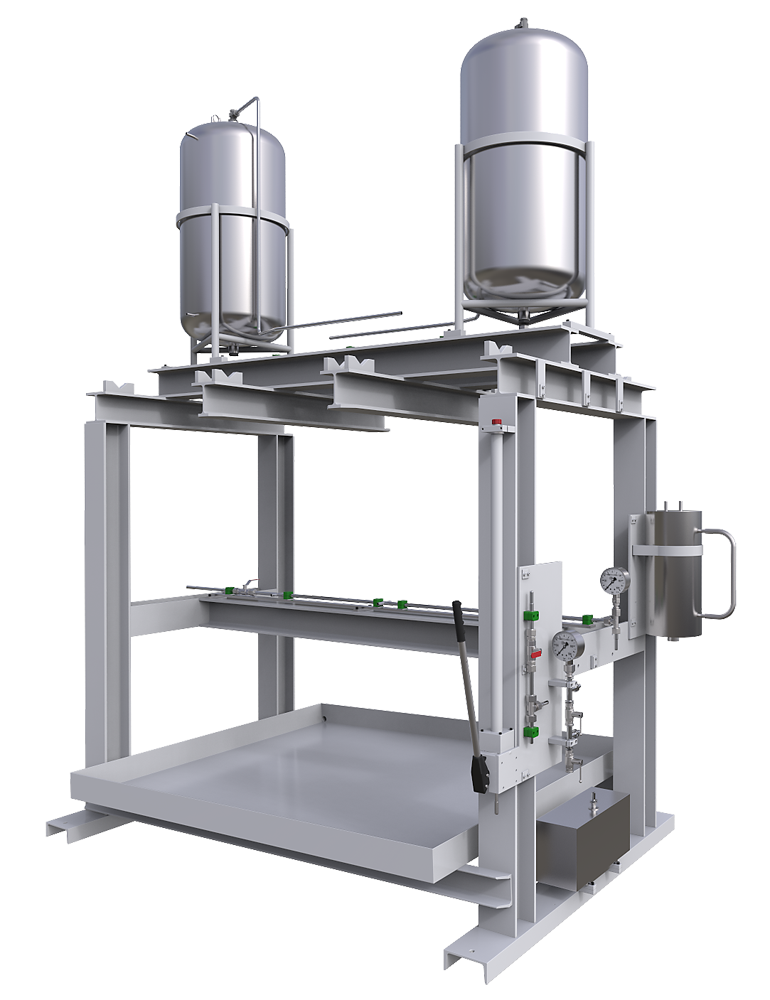

Standard snubbers

DAST

Introduction

Standard Snubbers (DAST) are used for all applications in conventional plants.

Snubbers are made with standard components, mainly available on stock.

Raw materials

Stainless steel rod with chemical nickel coating or chrominium

Body an internal parts in high quality carbon steel, surface protection by painting.

Dynamic characteristics at ambient temperature, 15°C to 35°C

Hereofter standard values, (others available on demand)

FN is the Nominal load of the snubber

Locking speed:

2 mm/s to 10 mm/s or as requested

Drag force at slow speeds, before locking

f < 500N if FN ≤ 30 kN

f < 2.0 % FN if 30 kN < FN ≤ 200 kN

f < 1.5 % FN if FN > 200 kN

Drift speed after locking,

at FN : 0.1 mm/s to 2.0 mm/s or as requested

Peak-to-peak motion under sinus alternating load FN from 3 to 10 Hz (depending on model)

< 4 mm if FN ≤ 100 kN

< 5 mm if FN ≤ 600 kN

< 6 mm up to FN = 600 kN

< 8 mm for stroke more than 300 mm

Environment conditions

Temperature:

Normal operating conditions : 0°C to +80°C

Minimum storage temperature : – 30°C

Humidity: 100 %

External pressure:

Service pressure : 1 bar

Accidental pressure : 5 bar

Total dose of radiations: 600 kGy

Stiffness

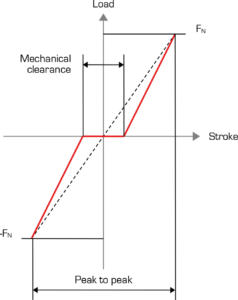

Snubber stiffness is defined according to the following diagram where:

Peak-to-Peak is the total stroke under alternative load

And Snubber Stiffness is: K=(2 x FN)/Peak-to-peak

| Model | Nominal Load FN | Stroke | Stiffness * |

| (kN) | (mm) | (kN/mm) | |

| DA1 | 14 | 100 | 13 |

| 200 | 11 | ||

| DA2 | 30 | 150 | 23 |

| 300 | 16 | ||

| DA3 | 47 | 150 | 33 |

| 300 | 25 | ||

| DA4 | 100 | 150 | 69 |

| 300 | 47 | ||

| DA5 | 200 | 150 | 124 |

| 300 | 76 |

* Tolerance on stiffness value : ± 25%

Permissible load in kN

The permissible load in terms of dynamic stress in the table below has been calculated in accordance with RCCM code vol. H level S1.

Load definition :

Normal/Disturbed – Level A/B: Here are estimated all loads due to normal functioning, including normal transitional regime during operation of the plant. And also some disturbed loads due to normal functioning of the plant.

Emergency : Level C: Here are estimated all loads outside to normal operation due to particulars situations, possibly safety shutdown earthquake.

Faulted : Level D: Here are estimated all loads due to accidental situations. The snubbers should undergo verification after such an event.

Stroke: Up to 300 mm

| Model | Total stroke | FN load level A/B/80°C |

Emergency load level C/80°C |

Faulted load level D/150°C |

| (mm) | (kN) | (kN) | (kN) | |

| DA1 ST | 100, 200 | 14 | 18 | 24 |

| DA2 ST | 150, 300 | 30 | 39 | 49 |

| DA3 ST | 150, 300 | 47 | 62 | 77 |

| DA4 ST | 150, 300 | 100 | 133 | 140 |

| DA5 ST | 150, 300 | 200 | 266 | 280 |

| DA6 ST | 150, 300 | 320 | 425 | 545 |

| DA7 ST | 150, 300 | 600 | 798 | 1020 |

Stroke: From 300 mm to 450 mm

| Model | Total stroke | FN load level A/B/80°C |

Emergency load level C/80°C |

Faulted load level D/150°C |

| (mm) | (kN) | (kN) | (kN) | |

| DA1 ST | 300 | 4 | 5 | 7 |

| DA2 ST | 450 | 15 | 20 | 25 |

| DA3 ST | 450 | 24 | 32 | 49 |

| DA4 ST | 450 | 60 | 80 | 100 |

| DA5 ST | 450 | 200 | 266 | 280 |

| DA6 ST | 450 | 320 | 425 | 545 |

| DA7 ST | 450 | 600 | 798 | 1020 |

Life under dynamic stress

The snubbers may be subject to the total dynamic loads below, without any adverse effect on operating, at temperature less than 80°C.

| Load (in % FN) | Number of cycles |

| 10% | 5 x 106 |

| 50% | 106 |

| 100% (level A/B) | 105 |

| 133% (level C) | 103 |

| (level D) | 102 |

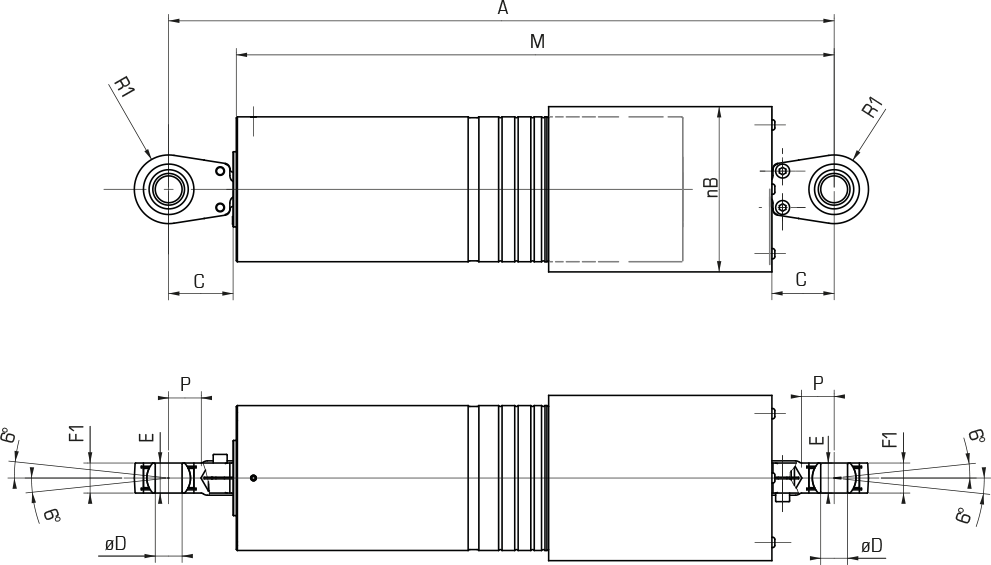

Dimensions

| Type | Nominal Load Level B |

Faulted Load Level D |

Stroke

|

A min |

A half stroke |

A max |

M half stroke |

Ø B

|

C

|

Ø D

|

E

|

F1

|

P

|

R1

|

Weight without bracket |

3D Model |

| (kN) | (kN) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (kg) | ||

| DA1ST-100 | 14 | 24 | 100 | 435 | 485 | 535 | 432 | 102 | 50 | 17 | 20 | 19 | 25 | 28 | 12 | 3D |

| DA1ST-200 | 14 | 24 | 200 | 618 | 718 | 818 | 665 | 102 | 50 | 17 | 20 | 19 | 25 | 28 | 16 | 3D |

| DA1ST-300 | 4 | 7 | 300 | 801 | 951 | 1101 | 898 | 102 | 50 | 17 | 20 | 19 | 25 | 28 | 20 | |

| DA2ST-150 | 30 | 49 | 150 | 555 | 630 | 705 | 577 | 115 | 50 | 20 | 25 | 23 | 25 | 28 | 21 | 3D |

| DA2ST-300 | 30 | 49 | 300 | 845 | 995 | 1145 | 942 | 115 | 50 | 20 | 25 | 23 | 25 | 28 | 30 | 3D |

| DA2ST-450 | 15 | 25 | 450 | 1135 | 1360 | 1585 | 1307 | 115 | 50 | 20 | 25 | 23 | 25 | 28 | 39 | |

| DA3ST-150 | 47 | 77 | 150 | 545 | 620 | 695 | 557 | 154 | 60 | 25 | 28 | 28 | 30 | 32 | 33 | 3D |

| DA3ST-300 | 47 | 77 | 300 | 795 | 945 | 1095 | 892 | 154 | 60 | 25 | 28 | 28 | 30 | 32 | 46 | 3D |

| DA3ST-450 | 24 | 49 | 450 | 1045 | 1270 | 1495 | 1207 | 154 | 60 | 25 | 28 | 28 | 30 | 32 | 59 | |

| DA4ST-150 | 100 | 140 | 150 | 590 | 665 | 740 | 592 | 170 | 70 | 30 | 32 | 30 | 38 | 39 | 49 | 3D |

| DA4ST-300 | 100 | 140 | 300 | 850 | 1000 | 1150 | 927 | 170 | 70 | 30 | 32 | 30 | 38 | 39 | 66 | 3D |

| DA4ST-450 | 60 | 100 | 450 | 1110 | 1335 | 1560 | 1262 | 170 | 70 | 30 | 32 | 30 | 38 | 39 | 83 | |

| DA5ST-150 | 200 | 280 | 150 | 710 | 785 | 860 | 677 | 220 | 105 | 45 | 43 | 40 | 55 | 58 | 82 | 3D |

| DA5ST-300 | 200 | 280 | 300 | 980 | 1130 | 1280 | 1022 | 220 | 105 | 45 | 43 | 40 | 55 | 58 | 106 | 3D |

| DA5ST-450 | 200 | 280 | 450 | 1250 | 1475 | 1700 | 1367 | 220 | 105 | 45 | 43 | 40 | 55 | 58 | 130 | |

| DA6ST-150 | 320 | 545 | 150 | 852 | 927 | 1002 | 774 | 254 | 150 | 60 | 63 | 55 | 75 | 82 | 120 | |

| DA6ST-300 | 320 | 545 | 150 | 852 | 927 | 1002 | 774 | 254 | 150 | 60 | 63 | 55 | 75 | 82 | 120 | |

| DA6ST-450 | 320 | 545 | 450 | 1424 | 1649 | 1874 | 1496 | 254 | 150 | 60 | 63 | 55 | 75 | 82 | 230 | |

| DA7ST-150 | 600 | 1020 | 150 | 1130 | 1205 | 1280 | 967 | 324 | 235 | 90 | 85 | 70 | 105 | 125 | 330 | |

| DA7ST-300 | 600 | 1020 | 300 | 1460 | 1610 | 1760 | 1372 | 324 | 235 | 90 | 85 | 70 | 105 | 125 | 400 | |

| DA7ST-450 | 600 | 1020 | 450 | 1790 | 2015 | 2240 | 1777 | 324 | 235 | 90 | 85 | 70 | 105 | 125 | 470 |

Other load, stroke or characteristics on demand.