General Guide

How to define your hydraulic equipment

For higher security, efficiency and reliability, we recommend keeping a reserve of 20% or 30% when you choose your force, stroke, and tank oil capacity.

Hydraulic equipment maintenance recommendations:

• Maintain regularly your hydraulic equipment. Keep it away from dust and corrosive or dry atmosphere.

• The equipment is warranted 1 year against manufacturing defects. Abusive or unsuitable use, modification of equipment and use of improper oil are not covered by the warranty.

• Hydraulic equipments must be only repaired by a qualified hydraulic technician.

• Our after sales service is at your disposal for any technical advise or equipment maintenance. Don’t hesitate to contact us.

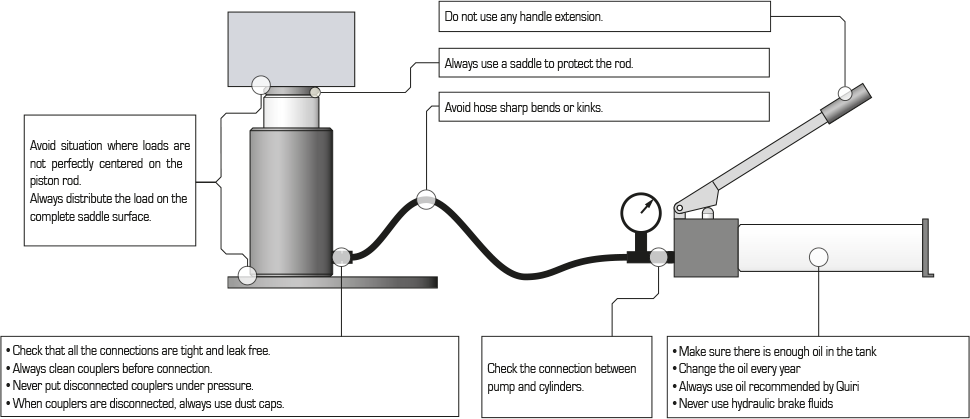

Security and use advice

Basics

Definitions – Formulas – Units

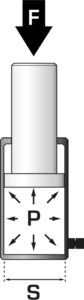

Force :

The force developed by a cylinder corresponds to hydraulic pressure times its effective area.

F(T) = P x S / 1000

F(kN) = P x S / 100

Units :

• F : Force in kN or in Ton

• P : Pressure in bar (kg/cm2)

• S : Effective area in cm2

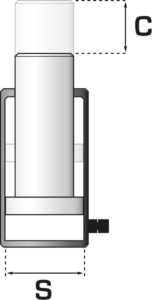

Cylinder oil capacity :

The volume required by a cylinder corresponds to its effective area times its stroke.

Vu = S x C

• Vu : Cylinder oil capacity in cm3

If your equipment is composed by several cylinders, you have to add oil capacity of each cylinder to get total oil capacity of the equipment.

Oil flow :

The oil flow is generated by the hydraulic pump. It is the oil volume that gives the pump in a certain period.

Units :

• l/min (liters/minute) : Electric, gasoline, air powered hydraulic pump

• cm3/stroke : Hand pump (about 40 strokes/min)

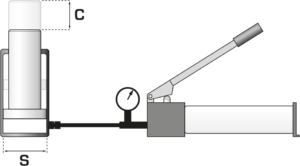

Cylinder’s stroke when driven by a hand pump :

The rod moves by a certain stroke (C) at each hand pump action.

This stroke depends on hand pump oil flow (Q in cm3 /pump stroke) and the cylinder effective area (S).

Units :

• C : Stroke in mm

• Q : Flow in cm3 /stroke

• S : Effective area in cm²

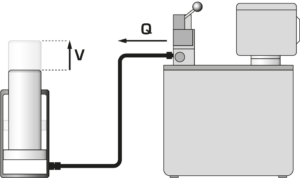

Cylinder travel speed :

The cylinder travel speed depends on pump oil flow (l/min) and cylinder effective area (S).

Units :

• V : Speed in mm/s

• Q : Flow in l/min

• S : Effective area in cm2

Units of measurements – US threadings

Conversion formulas :

Pressure :

1 bar = 10^5 Pa = 14,5 psi

1 Pa (Pascal) = 1 N/m2

1 psi = 0,069 bar

Force :

1 kgf (kg force) = 9,81 Newton

1 N (Newton) = 0,1019 kgf

1 kN = 1000 N = 101,9 kgf

Length :

1 mm = 0,039 in (inch)

1 in = 25,4 mm

| Inch | mm |

| 1/16 | 1,59 |

| 1/8 | 3,18 |

| 3/16 | 4,76 |

| 1/4 | 6,35 |

| 5/16 | 7,94 |

| 3/8 | 9,53 |

| 7/16 | 11,11 |

| 1/2 | 12,7 |

| 9/16 | 14,29 |

| 5/8 | 15,88 |

| 11/16 | 17,46 |

| 3/4 | 19,05 |

| 13/16 | 20,64 |

| 7/8 | 22,23 |

| 15/16 | 23,81 |

| 1 | 25,4 |

Threading equivalences :

| US Threading | Metric equivalent | ||

| Diameter | Thread pitch | ||

| 1/4 – 20 | UNC | 6,350 | 1,270 |

| 5/16 – 18 | UNC | 7,937 | 1,411 |

| 3/8 – 16 | UNC | 9,525 | 1,588 |

| 1/2 – 13 | UNC | 12,700 | 1,954 |

| 3/4 – 16 | UNF | 19,050 | 1,588 |

| 1 – 8 | UNC | 25,400 | 3,175 |

| 1 -12 | UNF | 25,400 | 2,117 |

| 1 1/4 – 7 | UNC | 31,750 | 3,629 |

| 1 1/2 – 16 | UN | 38,100 | 1,588 |

| 1 5/8 – 5 1/2 | UNS | 41,275 | 4,618 |

| 1 3/4 – 12 | UN | 44,450 | 2,117 |

| 2 1/4 – 14 | UNS | 57,150 | 1,814 |

| 2 3/4 – 16 | UN | 69,850 | 1,588 |

| 3 5/16 – 12 | UNS | 84,138 | 2,117 |

| 5 – 12 | UN | 127,000 | 2,117 |

| 6 7/8 – 12 | UN | 174,625 | 2,117 |