Double acting hydraulic cylinders HVB FPAI

(CNOMO type)

Operating pressure: 200 bar

Integrated front plate mounting.

Operating pressure :

Max. supply pressure: 200 bar

Test pressure: 315 bar

Permissible speed: Max. speed 5 m/min

Temperatures :

Minimum: -20°C

Maximum: +80°C with Standard seal, +150°C with Viton seal.

Fluids :

HM-HL hydraulic mineral oils 10 to 40 Cst at 50°C.

Low flammability fluids class C or D

Filtration: ≤ 200 microns

Connection: In BSPP cylindrical gas with counterbore for sealing ring.

Commissioning:

To ensure correct operation, air in both cylinder chambers should be purged by loosening the fittings, oil unpressurized. When the fluid is free of emulsion, retighten the fittings.

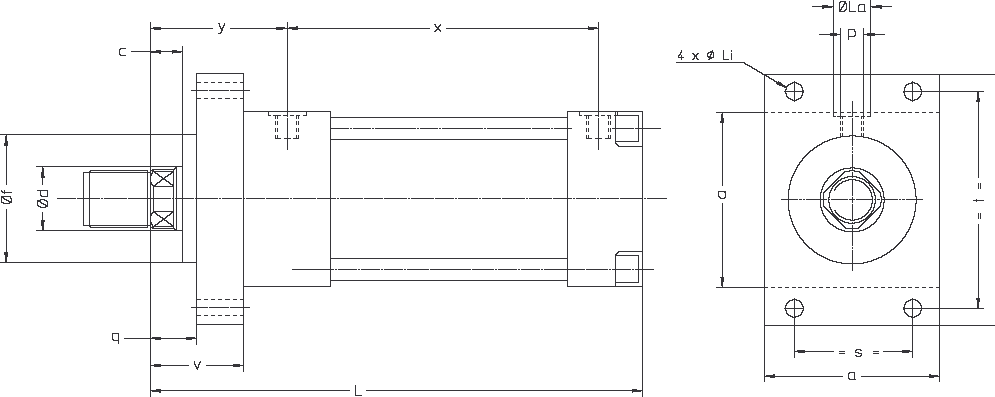

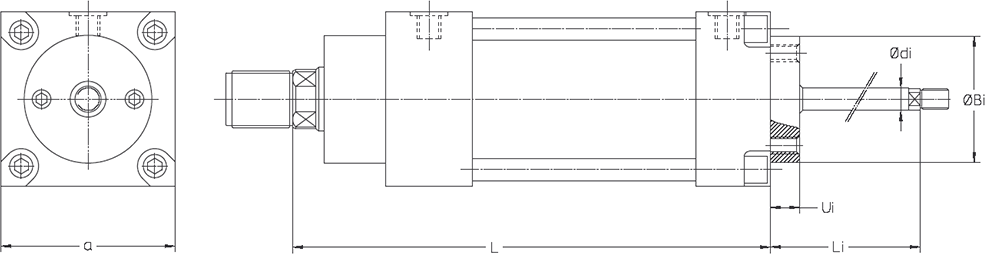

| Bore | Units | 25 | 32 | 40 | 50 | 63 | 80 | 100 | 125 |

| ød (ø Rod) | (mm) | 16 | 18 | 22 | 28 | 36 | 45 | 56 | 70 |

| øf | (mm) | 36 | 40 | 45 | 56 | 63 | 80 | 100 | 125 |

| a | (mm) | 45 | 56 | 63 | 75 | 85 | 106 | 125 | 160 |

| b | (mm) | 70 | 86 | 100 | 115 | 124 | 160 | 185 | 230 |

| p | G1/8 | G1/8 | G1/4 | G1/4 | G3/8 | G3/8 | G1/2 | G1/2 | |

| øLi | (mm) | 6.6 | 9 | 11 | 11 | 14 | 18 | 20 | 22 |

| øLa | (mm) | 19 | 19 | 25 | 25 | 28 | 28 | 34 | 34 |

| x | (mm) | 34 | 45 | 45 | 53 | 56 | 63 | 70 | 80 |

| y | (mm) | 46 | 48 | 55 | 57 | 71 | 74 | 81 | 93 |

| s | (mm) | 34 | 36 | 45 | 50 | 65 | 80 | 97.5 | 125 |

| t | (mm) | 56 | 71 | 80 | 95 | 104 | 132 | 155 | 195 |

| q | (mm) | 16 | 16 | 20 | 16 | 21 | 22 | 24 | 27 |

| v | (mm) | 28 | 32 | 40 | 40 | 45 | 50 | 58 | 63 |

| c | (mm) | 12 | 12 | 15 | 12 | 17 | 18 | 20 | 23 |

| L | (mm) | 92 | 102 | 115 | 125 | 145 | 152 | 177 | 198 |

Strokes

| Bore | 25 | 32 | 40 | 50 | 63 | 80 | 100 | 125 | |

Stroke Tolerance+2 0 |

5 | X | X | X | X | X | X | X | X |

| 10 | X | X | X | X | X | X | X | X | |

| 16 | X | X | X | X | X | X | X | X | |

| 25 | X | X | X | X | X | X | X | X | |

| 40 | X | X | X | X | X | X | X | X | |

| 63 | X | X | X | X | X | X | X | ||

| 100 | X | X | X | X | X | X | X | ||

| 160 | X | X | X | X | X | X | |||

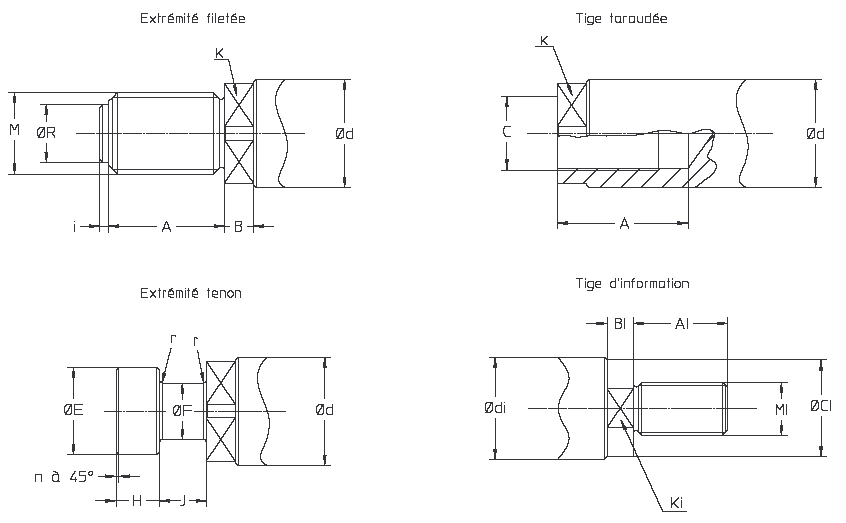

Rod ends

| Bore | Units | 25 | 32 | 40 | 50 | 63 | 80 | 100 | 125 |

| ød (ø Rod) | (mm) | 16 | 18 | 22 | 28 | 36 | 45 | 56 | 70 |

| ød / Al | (mm) | 10 | 10 | 12 | 12 | 12 | 12 | 16 | 16 |

| A | (mm) | 20 | 20 | 25 | 32 | 40 | 50 | 63 | 80 |

| øR | (mm) | 9.5 | 9.5 | 13 | 17 | 23.5 | 29.5 | 38.5 | 48.5 |

| øCl | (mm) | 9.5 | 9.5 | 11.5 | 11.5 | 11.5 | 11.5 | 15 | 15 |

| i | (mm) | 2.5 | 2.5 | 3 | 3 | 3 | 4 | 5 | 5 |

| M | (mm) | M12 x 1.25 | M12 x 1.25 | M16 x 1.5 | M20 x 1.5 | M27 x 2 | M33 x 2 | M42 x 2 | M56 x 2 |

| C | (mm) | M8 x 1.25 | M8 x 1.25 | M10 x 1.5 | M16 x 1.5 | M20 x 1.5 | M27 x 2 | M33 x 2 | M42 x 2 |

| Ml | (mm) | M8 x 1.25 | M8 x 1.25 | M10 x 1.25 | M10 x 1.5 | M10 x 1.5 | M10 x 1.5 | M12 x 1.25 | M12 x 1.25 |

| n | (mm) | 0.2 | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 | 0.5 | 0.5 |

| øE | (mm) | 14 | 15 | 18 | 22.5 | 28 | 35.5 | 45 | 56 |

| øF | (mm) | 8 | 9 | 11.2 | 14 | 18 | 22.4 | 28 | 35.5 |

| H/J | (mm) | 6 | 6 | 8 | 10 | 12.5 | 16 | 20 | 25 |

| r | (mm) | 0.3 | 0.3 | 0.5 | 0.5 | 0.8 | 0.8 | 1.2 | 1.2 |

| B | (mm) | 8 | 8 | 8 | 8 | 12.5 | 12.5 | 14 | 14 |

| Bl | (mm) | 5 | 5 | 6 | 6 | 6 | 6 | 8 | 8 |

| K | (mm) | 12 | 13 | 17 | 22 | 30 | 36 | 46 | 60 |

| Ki | (mm) | 8 | 8 | 10 | 10 | 10 | 10 | 13 | 13 |