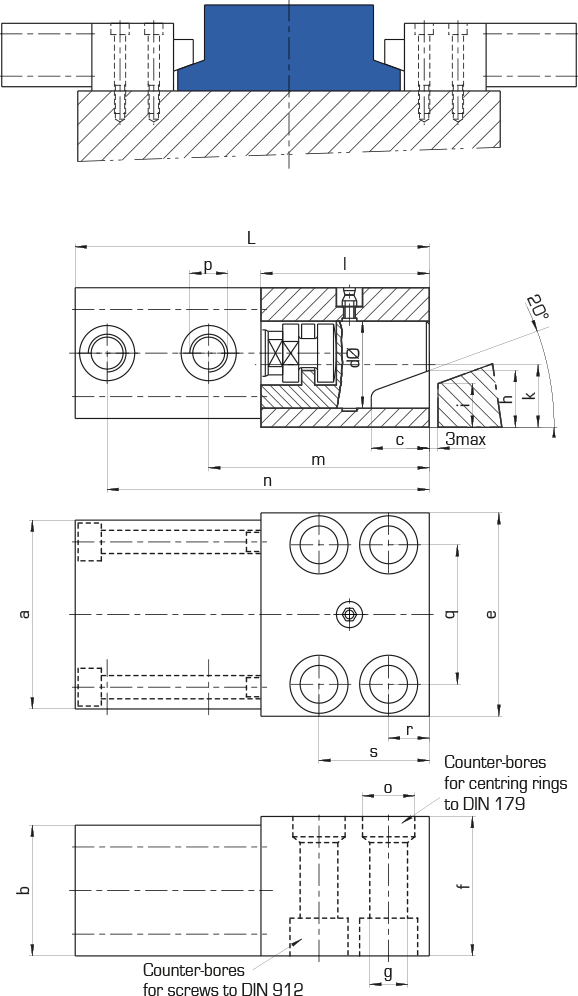

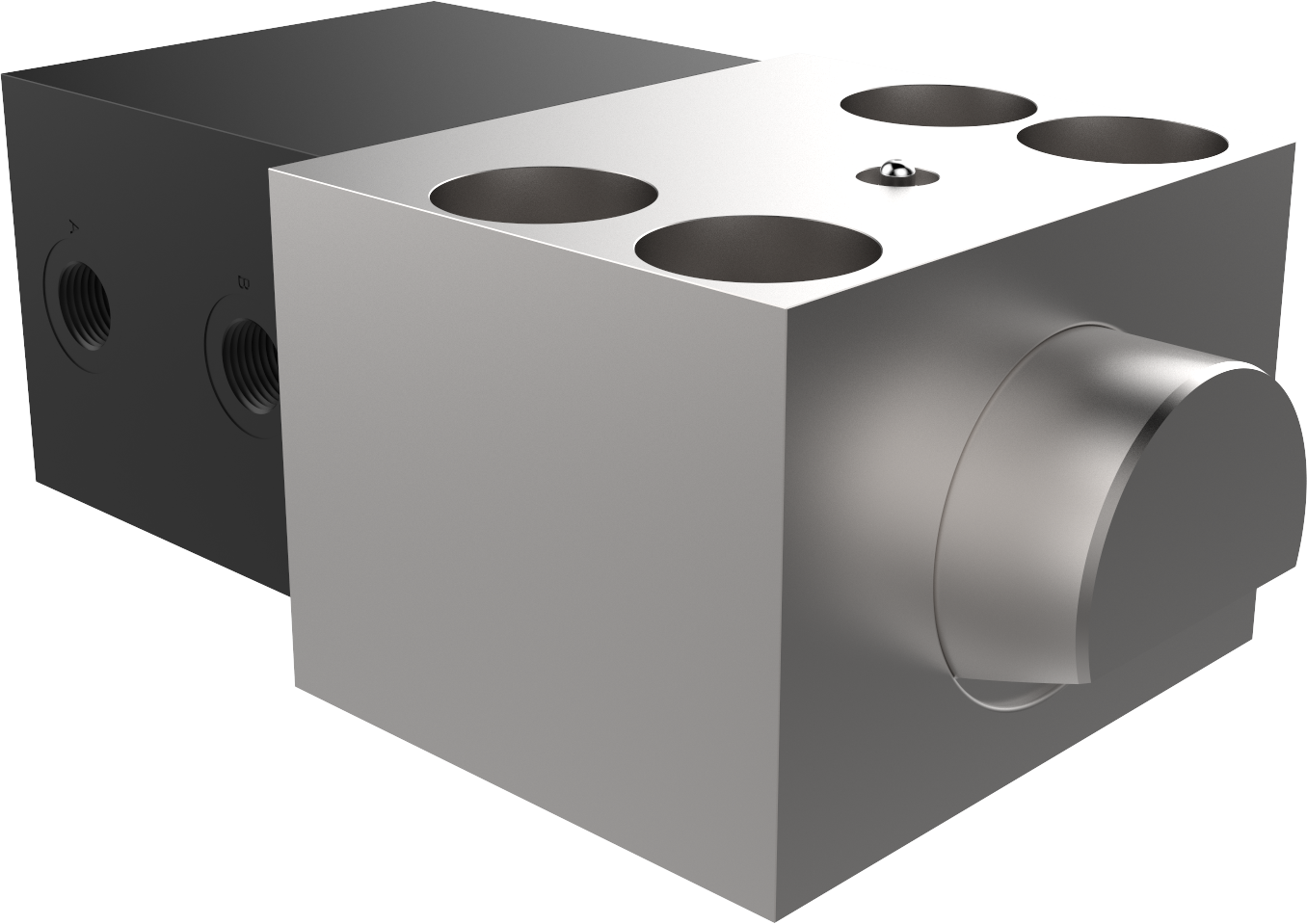

Corner clamping element KSM

Double-acting with no position control

Clamping force 25kN to 630 kN

Corner clamping elements make it possible to fasten a fixture safely and hold it when there is no pressure. These elements are mainly used for clamping press tools or machining fixtures.

A guiding element is screwed to a double-acting block clamp.

Clamping is maintained thanks to the slope of the end of the rod, by wedging

• 20 to 40 mm travel

• clamping force up to 630 kN

• compact size

• max. service pressure 275/350 bar

• hardened steel rod

• version with no position control

Important recommendations

Due to the shearing forces that occur during corner clamping, the tools must be secured to prevent movement, for instance using positioning pins or mechanical stops.

The elements must be protected from the entry of dust, chips, coolant, etc.

The locking rod must be greased at regular intervals, when the rod is retracted.

Caution: in the event of an operating error, the rod may retract fully and the tool would fall.

| Thrust force

max |

Retaining force (8.8 screw) | Pressure

max |

Travel

max |

Rod

øD |

Type | Reference | |||||||||||||||||||

| a

|

b

|

c

|

d

|

e

|

f

|

g

|

h

|

i

|

k

|

l

|

L

|

m

|

n

|

o

ø H7 x Depth |

p

±0.02 for øo |

q

|

r

|

s

|

|||||||

| kN | kN | bar | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | |||

| 25 | 35 | 350 | 20 | 25 | KSM-025 | M 530-1-025 | 65 | 45 | 20 | 30 | 70 | 48 | 13 | 19.5 | 15 | 21.5 | 58 | 122 | 76 | 111 | 18 x 7 | G1/4 | 48 | 14 | 38 |

| 50 | 65 | 275 | 25 | 40 | KSM-040 | M 530-1-040 | 85 | 63 | 25 | 40 | 95 | 65 | 17 | 23.5 | 18 | 28 | 78 | 157 | 102 | 146 | 26 x 9 | G1/4 | 65 | 16 | 46 |

| 100 | 130 | 350 | 25 | 50 | KSM-050 | M 530-1-050 | 100 | 75 | 26 | 55 | 120 | 80 | 21 | 30.5 | 25 | 37 | 100 | 190 | 127 | 177 | 30 x 11 | G1/4 | 85 | 20 | 58 |

| 160 | 210 | 350 | 30 | 63 | KSM-063 | M 530-1-063 | 125 | 95 | 32 | 70 | 150 | 105 | 26 | 37 | 30 | 49 | 125 | 227 | 151 | 210 | 35 x 11 | G1/2 | 106 | 25 | 75 |

| 250 | 320 | 350 | 32 | 80 | KSM-080 | M 530-1-080 | 160 | 120 | 40 | 80 | 200 | 125 | 33 | 38 | 30 | 55 | 150 | 267 | 184 | 246 | 48 x 13 | G1/2 | 140 | 26 | 78 |

| 400 | 520 | 350 | 40 | 100 | KSM-100 | M 530-1-100 | 200 | 150 | 45 | 100 | 240 | 160 | 39 | 60 | 50 | 75 | 180 | 310 | 215 | 285 | 55 x 16 | G1/2 | 180 | 32 | 95 |

| 630 | 820 | 350 | 40 | 125 | KSM-125 | M 530-1-125 | 230 | 180 | 50 | 125 | 280 | 190 | 45 | 70 | 60 | 85 | 225 | 375 | 272 | 344 | 62 x 16 | G1/2 | 210 | 38 | 108 |