Lifting light alloy cylinders 500 bar

Other products

Access Lifting light alloy cylinders 500 bar 's products

Access selection

Back to Lifting equipments

Hollow piston single acting cylinders, load return – 500 bar – SLC

Light alloy

• Single acting, load return

• Maximum pressure 600 bar (stroke to be limited at 80% of the whole stroke)

• Corrosion resistant light alloy body

• Chrome plated piston rod for cylinder 13 T

• Corrosion resistant light alloy piston rod for cylinders 35, 55, 80 T

• Wiper seals

• Delivered in standard without coupler

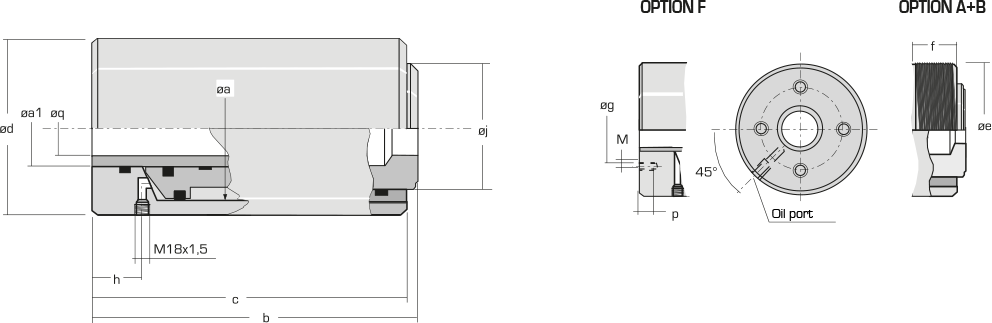

A+B : Body collar thread with rubber protection *

F : 4 base threaded mounting holes

| Cylinder category | Working force

500 bar |

Maximum force

600 bar |

Stroke | Effective area | Oil volume | Reference | Dimensions (mm) | Options | Weight | |||||||||

| a | b | c | d | h | j | a1 | q | Option A * | Option F | |||||||||

| e | f | M x p on Øg | ||||||||||||||||

| Tons | kN | kN | mm | cm2 | cm3 | kg | ||||||||||||

| 13 | 129,6 | 155,6 | 100 | 25,92 | 260 | SLC 13/100 | 70 | 225 | 222 | 100,5 | 28 | 55 | 40 | 27 | M100 x 2 | 40 | M8 x 20 on Ø 65 | 6,5 |

| 35 | 333,8 | 400,5 * | 100 | 66,76 | 670 | SLC 35/100 | 110 | 240 | 236 | 145,5 | 43 | 85 | 60 | 44 | 145 x 3 ** | 45 | M10 x 22 on Ø 90 | 10,2 |

| 200 | 1340 | SLC 35/200 | 370 | 364 | 48 | 14,6 | ||||||||||||

| 55 | 548,8 | 658,5 * | 100 | 109,76 | 1100 | SLC 55/100 | 140 | 270 | 266 | 190,5 | 55 | 110 | 75 | 55 | 190 x 4 ** | 50 | M10 x 22 on Ø 120 | 22 |

| 80 | 816,8 | 980,1 * | 100 | 163,36 | 1640 | SLC 80/100 | 170 | 290 | 285 | 230,5 | 55 | 140 | 90 | 70 | 225 x 5 ** | 50 | M12 x 25 on Ø 150 | 32,2 |

* For 35, 55, and 80 T cylinders with Option A, maximum pressure is 500 bar

** Semi-trapezoidal threading