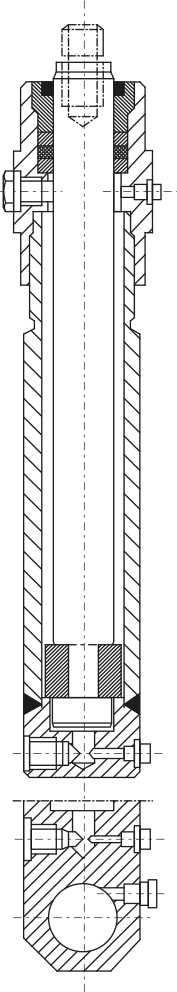

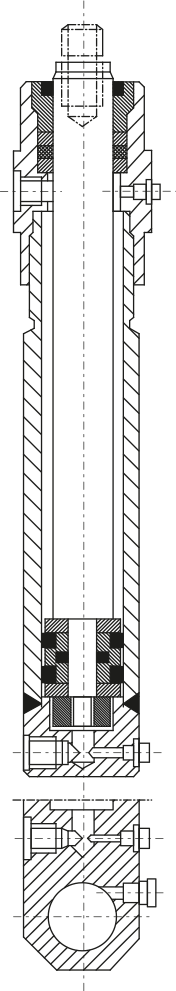

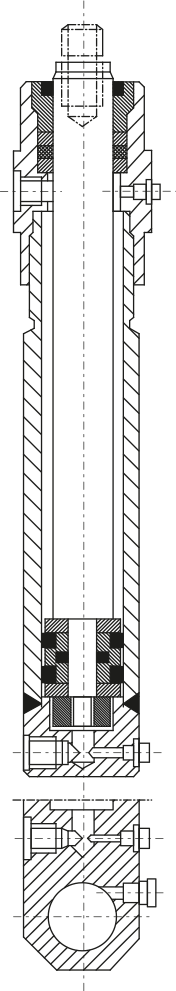

500V series double-acting cylinders

DE - 500V

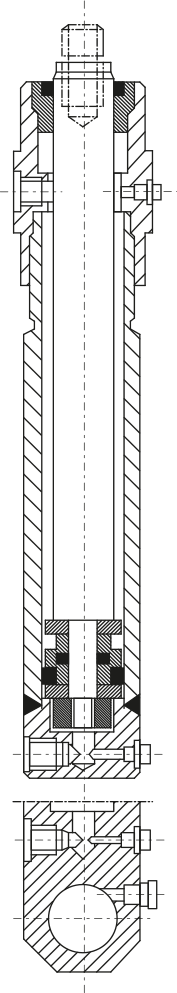

High-performance cylinders suitable for all applications, particularly in very harsh operating conditions with high loads in small spaces (steelworks, public works, presses, etc.).

• Wide recesses and bronze guiding

• Chevron seals on piston and rod for standard version

• Pressure in intermittent service : 500 bar

• Intensive operating : 400 bar

• Maximum speed : 0,5 m/s with standard seals, up to 2 m/s with special seals

• Maximum temperature : 100°C with standard seals, up to 200°C with viton seals

• A choice of three rod diameters per bore from ∅50, with the differential rod corresponding to common cases. Standardized bore and rod.

• Other threads k

• Metric thread on Ø e

• Damping (damping stroke to be specified)

• Double-rod cylinder

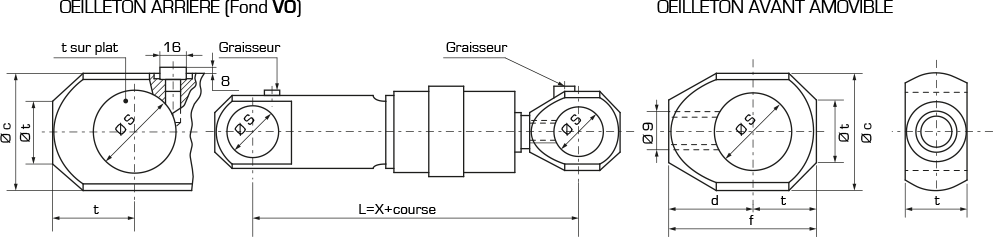

• The rear endeye on VO-type cylinders can be supplied in the following versions :

– Ø S smooth

– with ball joint, snap ring and grease nipple

– or with bronze bushing

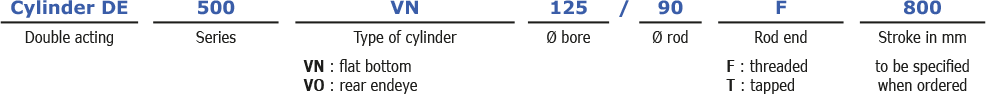

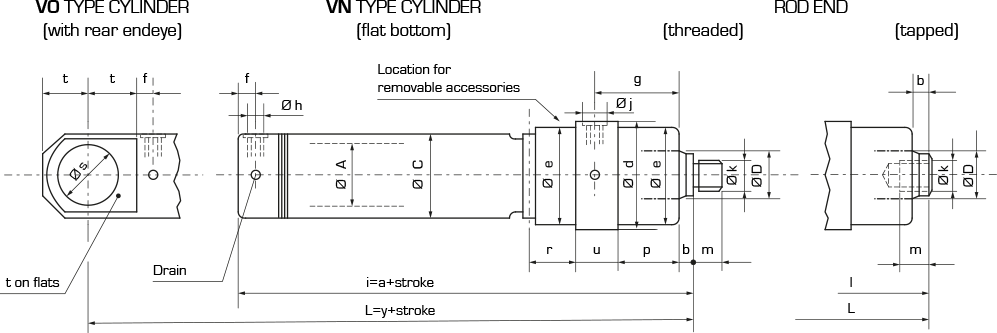

Designation

Dimensions

| Bore Ø A | 25 | 32 | 40 | 50 | 63 | 80 | 100 | 125 | 140 | 160 | 200 | |

| Rod Ø D | for tension | – | – | – | 32 | 40 | 50 | 63 | 80 | 90 | 100 | 125 |

| differential | 18 | 22 | 28 | 36 | 45 | 56 | 70 | 90 | 100 | 110 | 140 | |

| force (pushing) | – | – | – | 40 | 50 | 63 | 80 | 100 | 110 | 125 | 160 | |

| a | 128 | 148 | 175 | 190 | 235 | 275 | 315 | 385 | 405 | 440 | 540 | |

| b | 8 | 8 | 10 | 10 | 15 | 15 | 15 | 20 | 20 | 25 | 30 | |

| c | 35 | 42 | 52 | 70 | 83 | 108 | 132 | 170 | 190 | 212 | 270 | |

| d | 50 | 60 | 70 | 85 | 105 | 135 | 165 | 210 | 240 | 260 | 330 | |

| e | 42 | 52 | 58 | 75 | 95 | 116 | 146 | 186 | 208 | 235 | 290 | |

| f | 11 | 12 | 16 | 18 | 20 | 22 | 25 | 35 | 35 | 35 | 40 | |

| g | 45 | 47.5 | 56.5 | 67.5 | 82 | 98 | 115 | 135 | 143 | 160 | 195 | |

| h | G 1/4 | G 1/4 | G 3/8 | G 3/8 | G 1/2 | G 1/2 | G 3/4 | G 3/4 | G 3/4 | G 1 | G 1 | |

| j | 21 | 21 | 24 | 24 | 31 | 31 | 36 | 36 | 36 | 42 | 42 | |

| k | M 12 x 1 | M 14 x 1 | M 18 x 1.5 | M 24 x 1.5 | M 27 x 1.5 | M 35 x 1.5 | M 45 x 1.5 | M 55 x 1.5 | M 64 x 1.5 | M 72 x 1.5 | M 90 x 2 | |

| m | 12 | 14 | 18 | 24 | 27 | 35 | 45 | 55 | 64 | 72 | 90 | |

| p | 17.5 | 22.5 | 32.5 | 42.5 | 60 | 75 | 90 | 100 | 110 | 125 | 155 | |

| r mini/maxi | 15/20 | 20/25 | 25/30 | 35/40 | 45/50 | 50/60 | 60/70 | 80/90 | 80/90 | 90/100 | 110/120 | |

| s | 26 | 30 | 35 | 47 | 62 | 75 | 90 | 120 | 13 | 150 | 180 | |

| t | 18 | 22 | 28 | 35 | 45 | 55 | 70 | 90 | 100 | 110 | 140 | |

| u | 50 | 50 | 50 | 50 | 50 | 50 | 55 | 70 | 70 | 70 | 80 | |

| y | 147 | 170 | 203 | 225 | 280 | 325 | 385 | 475 | 505 | 550 | 680 | |

| Stroke mini | 20 | 20 | 30 | 30 | 50 | 50 | 50 | 50 | 100 | 100 | 100 | |

| Thread on Ø e | M 42 x 1.5 | M 52 x 1.5 | M 58 x 2 | M 75 x 2 | M 94 x 2 | M 112 x 3 | M 140 x 2 | M 186 x 3 | M 206 x 2 | M 200 x 3 | M 205 x 3 | |

References

| Bore / Rod | 25/18 | 32/22 | 40/28 | 50/32 | 50/36 | 50/40 | 63/40 | 63/45 | 63/50 | 80/50 | 80/56 | |

| VN bottom | F Rod | 151010 | 151016 | 141062 | 142041 | 142141 | 142050 | 142056 | 142059 | 142065 | 143060 | 143094 |

| T Rod | 151011 | 151017 | 141063 | – | 142142 | 142051 | – | 142060 | 142066 | – | 143095 | |

| VO bottom | F Rod | 151012 | 151018 | 141064 | 142042 | 142143 | 142052 | 142057 | 142061 | 142067 | 143051 | 143096 |

| T Rod | 151013 | 151019 | 141065 | – | 142144 | 142053 | – | 142062 | 142068 | – | 143097 | |

| Bore / Rod | 80/63 | 100/63 | 100/70 | 100/80 | 125/80 | 125/90 | 125/100 | 140/90 | 140/100 | 140/110 | 160/100 | |

| VN bottom | F Rod | 143059 | 144050 | 144053 | 144059 | 145050 | 145053 | 145059 | 146040 | 146043 | 146049 | 146055 |

| T Rod | 143060 | – | 144054 | 144060 | – | 145054 | 145060 | – | 146044 | 146050 | – | |

| VO bottom | F Rod | 143061 | 144051 | 144055 | 144061 | 145051 | 145055 | 145061 | 146041 | 146045 | 146051 | 146056 |

| T Rod | 143062 | – | 144056 | 144062 | – | 145056 | 145062 | – | 146046 | 146052 | – | |

| Bore / Rod | 160/110 | 160/125 | 200/125 | 200/140 | 200/160 | |

| VN bottom | F Rod | 146058 | 146064 | 147055 | 147058 | 147064 |

| T Rod | 146060 | 146065 | – | 147059 | 147065 | |

| VO bottom | F Rod | 146061 | 146066 | 147056 | 147060 | 147066 |

| T Rod | 146062 | 146067 | – | 147061 | 147067 | |

Technical specifications

Cylinder force in 104 N at 500 bar

| Bore | 25 | 32 | 40 | 50 | 63 | 80 | 100 | 125 | 140 | 160 | 200 | |

| Section in cm2 | 4.9 | 8.04 | 12.56 | 19.63 | 31.17 | 50.26 | 78.54 | 122.71 | 153.93 | 201.06 | 314.16 | |

| Pushing force (104N) | 2.40 | 3.94 | 6.16 | 9.62 | 15.28 | 24.64 | 38.50 | 60.15 | 75.46 | 98.56 | 154 | |

| Rod for tension | Section (cm2) | – | – | – | 11.59 | 18.6 | 30.63 | 47.36 | 72.45 | 90.32 | 122.52 | 191.44 |

| Return force (104N) | – | – | – | 5.68 | 9.12 | 15 | 23.22 | 35.5 | 44.27 | 60.06 | 93.85 | |

| Differential

rod |

Section (cm2) | 2.36 | 4.24 | 6.4 | 9.45 | 15.26 | 25.63 | 40.05 | 59.1 | 75.39 | 106 | 160.22 |

| Return force (104N) | 1.16 | 2.08 | 3.14 | 4.7 | 7.48 | 12.81 | 19.64 | 28.96 | 36.95 | 51.97 | 78.54 | |

| Strong rod | Section (cm2) | – | – | – | 7.07 | 11.53 | 19.09 | 28.27 | 44.17 | 58.9 | 78.34 | 113.1 |

| Return force (104N) | – | – | – | 3.46 | 5.65 | 9.36 | 13.86 | 21.65 | 28.87 | 38.4 | 55.45 | |

Cylinder weight in Kg

| Bore | 25 | 32 | 40 | 50 | 63 | 80 | 100 | 125 | 140 | 160 | 200 | |

| VN CYLINDER TYPE | P | 1.37 | 2.6 | 3.6 | 6.5 | 12 | 21 | 40 | 81 | 106 | 142 | 275 |

| VO CYLINDER TYPE | P | 1.47 | 2.8 | 4 | 7.3 | 13 | 25 | 47 | 95 | 125 | 166 | 330 |

| Traction rod | Z | – | – | – | 0.021 | 0.027 | 0.045 | 0.069 | 0.12 | 0.15 | 0.18 | 0.3 |

| Differential rod | Z | 0.006 | 0.007 | 0.011 | 0.022 | 0.03 | 0.048 | 0.074 | 0.13 | 0.16 | 0.19 | 0.32 |

| Strong rod | Z | – | – | – | 0.024 | 0.032 | 0.054 | 0.083 | 0.14 | 0.17 | 0.21 | 0.35 |

Determining the weight of a cylinder : Weight in kg = P + (Z x stroke in mm)

Numerical example :

Bore Ø 125 VN Type : P=81

Per mm of stroke : Z=0,14

Stroke in mm : 800

Weight =80+(0,14*800) = 193 kg