SUPER COMPACT RGC

Other products

Access SUPER COMPACT RGC 's products

Access selection

Back to Gas Springs

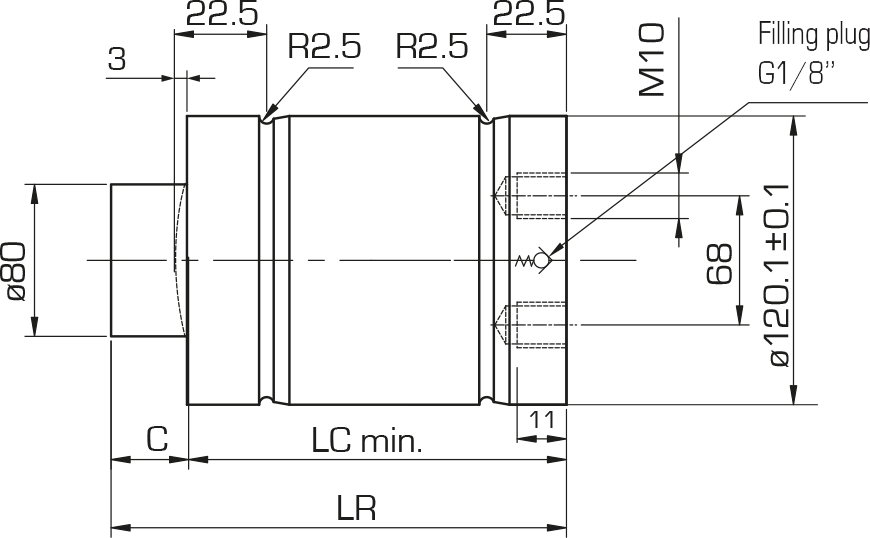

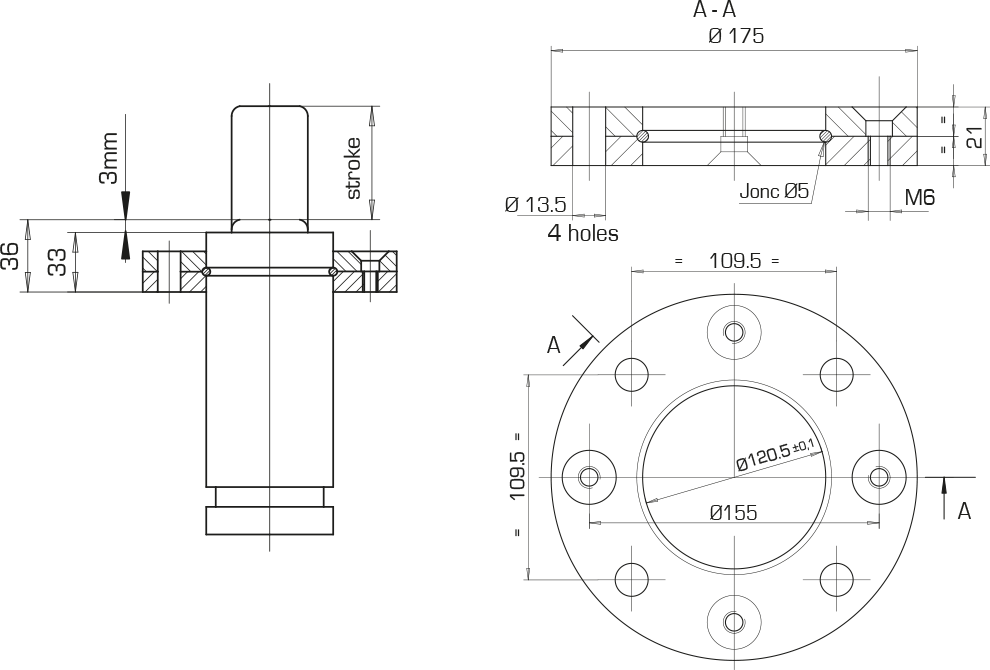

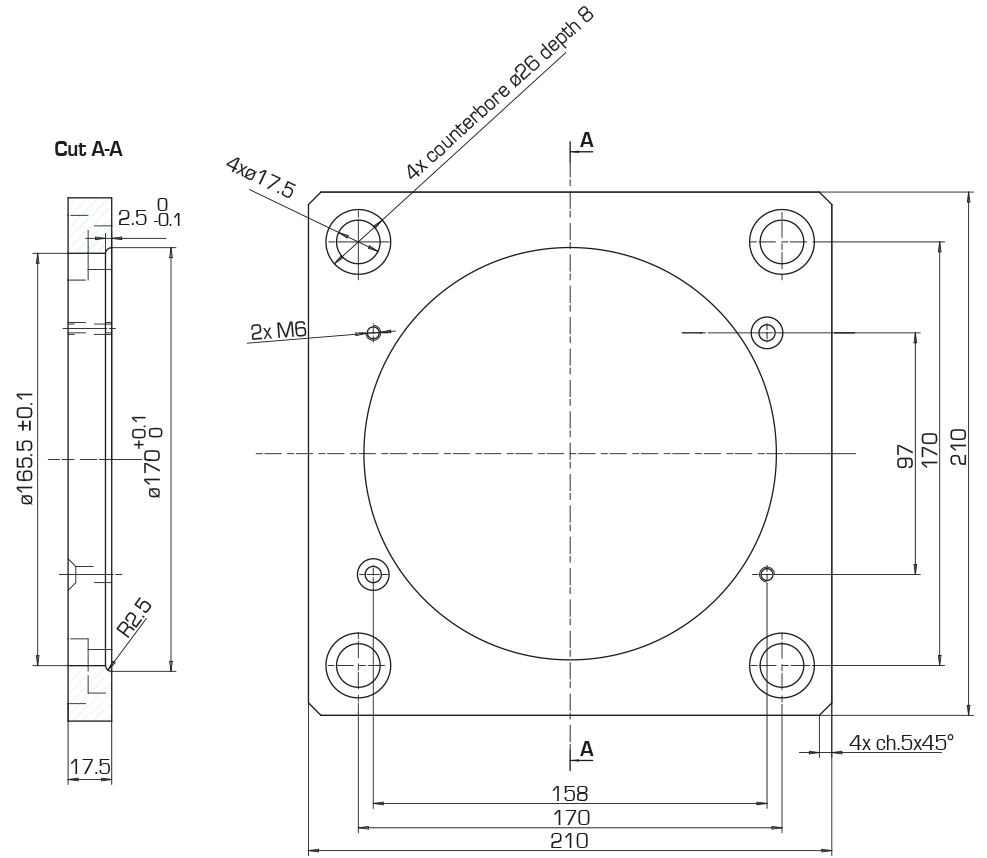

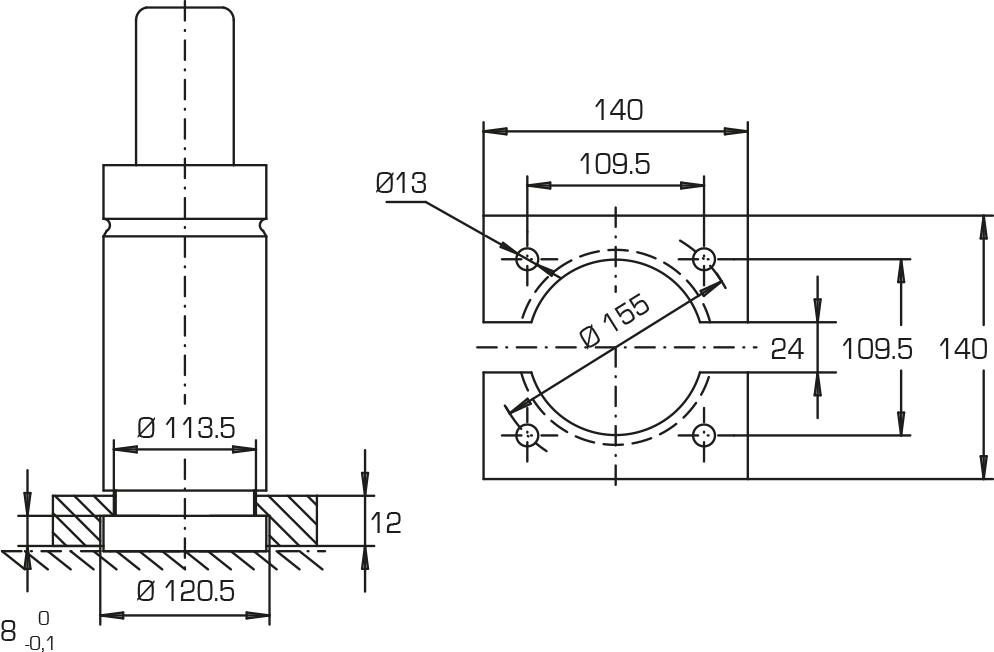

RGC 11800 gas spring

| Type | Force

daN |

Stroke

C mm |

Order code | Pressure

MPa (bar) |

Force F1

N * |

Force F2

N * |

LR | LC | Weight

Kg |

| RGC | 11800 | 10 | 443172/000 | 15

(150) (!) |

117 810 | 155 360 | 100 | 90 | 5.70 |

| 16 | 443173/000 | 159 480 | 126 | 110 | 6.10 | ||||

| 25 | 443174/000 | 166 760 | 155 | 130 | 6.50 | ||||

| 32 | 443175/000 | 164 250 | 187 | 155 | 7.60 | ||||

| 40 | 443176/000 | 164 150 | 220 | 180 | 8.10 | ||||

| 50 ** | 443177/000 | 164 530 | 260 | 210 | 8.70 |

* (N) = Kgf x 9.80665 | (Kgf)=N x 0.101972 | 1daN=1 x 101N | 1bar=1 x 10-1MPa

** DESP 97/23/EC Category II : these gas springs must be returned to the manufacturer for repairing.

Example of order: RGC 11800 C50

Spare Kit : 896513/000.

Composition : Seals, valve and lubricant.

(!) There is a blue sticker on the gas spring body when it is inflated with a special pressure (<15 MPa)

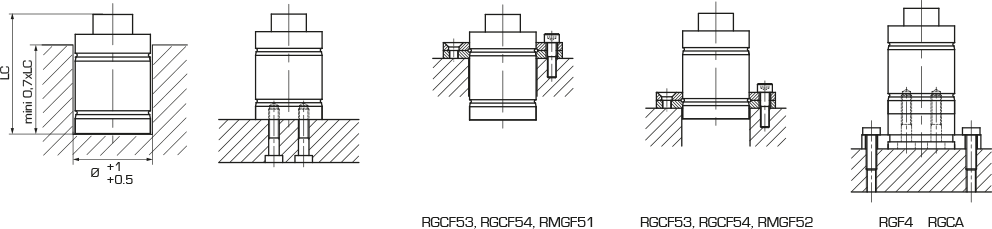

CAUTION : If you fix RGC type by bottom thread, gas spring’s bottom surface should lay completely on the die. RGC with stroke > 25mm should be attached to the die with screws or flanges (no drop-in mounting).